Select by application scenario

Select by Mechanical Series

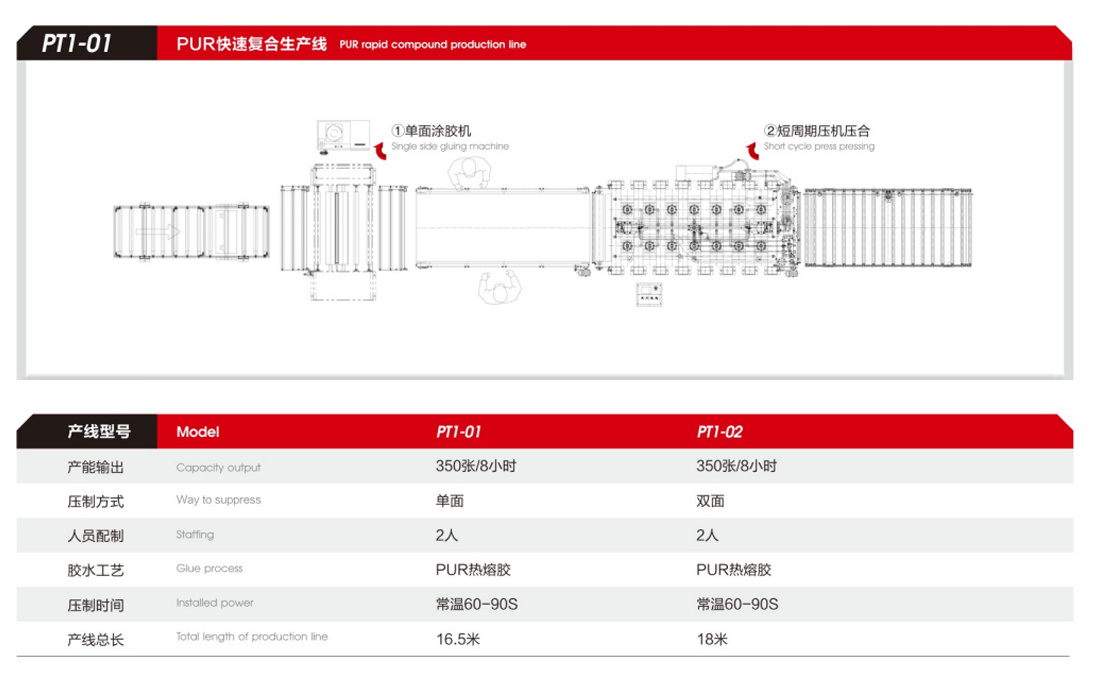

PT1-01

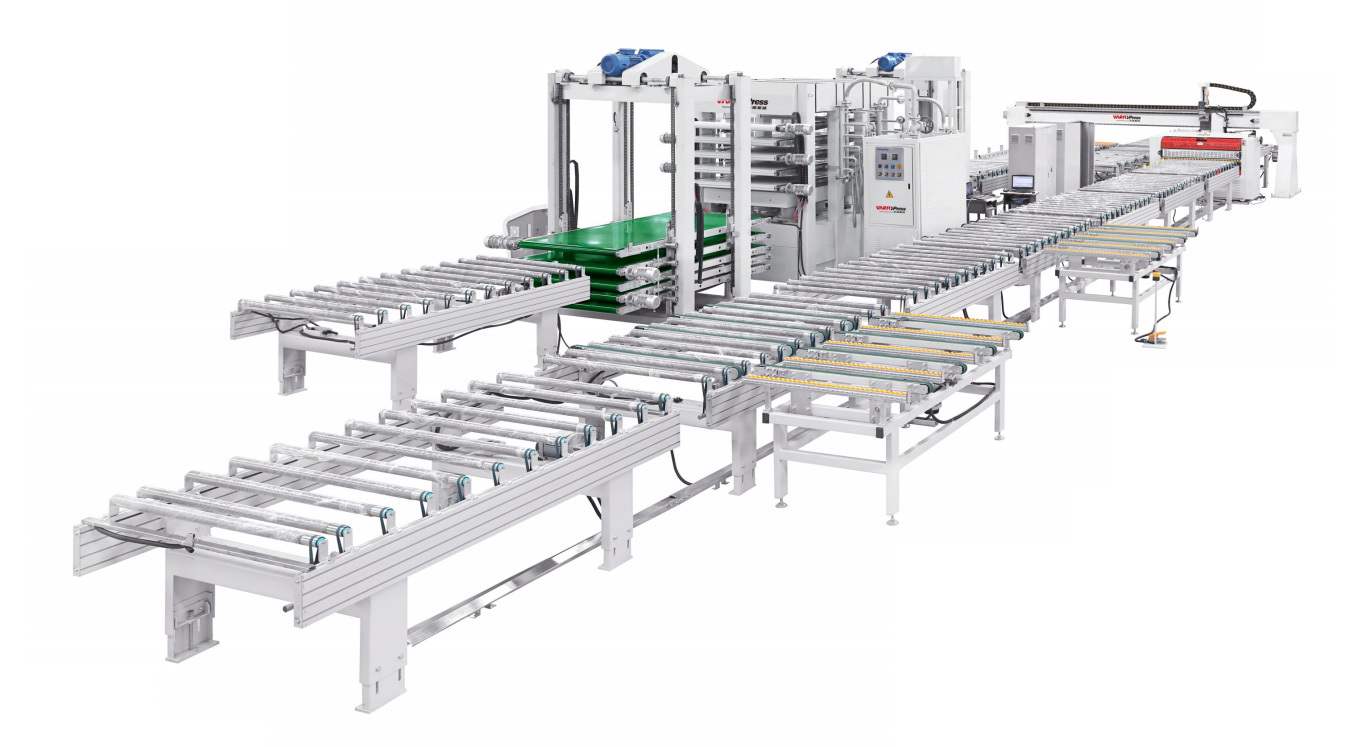

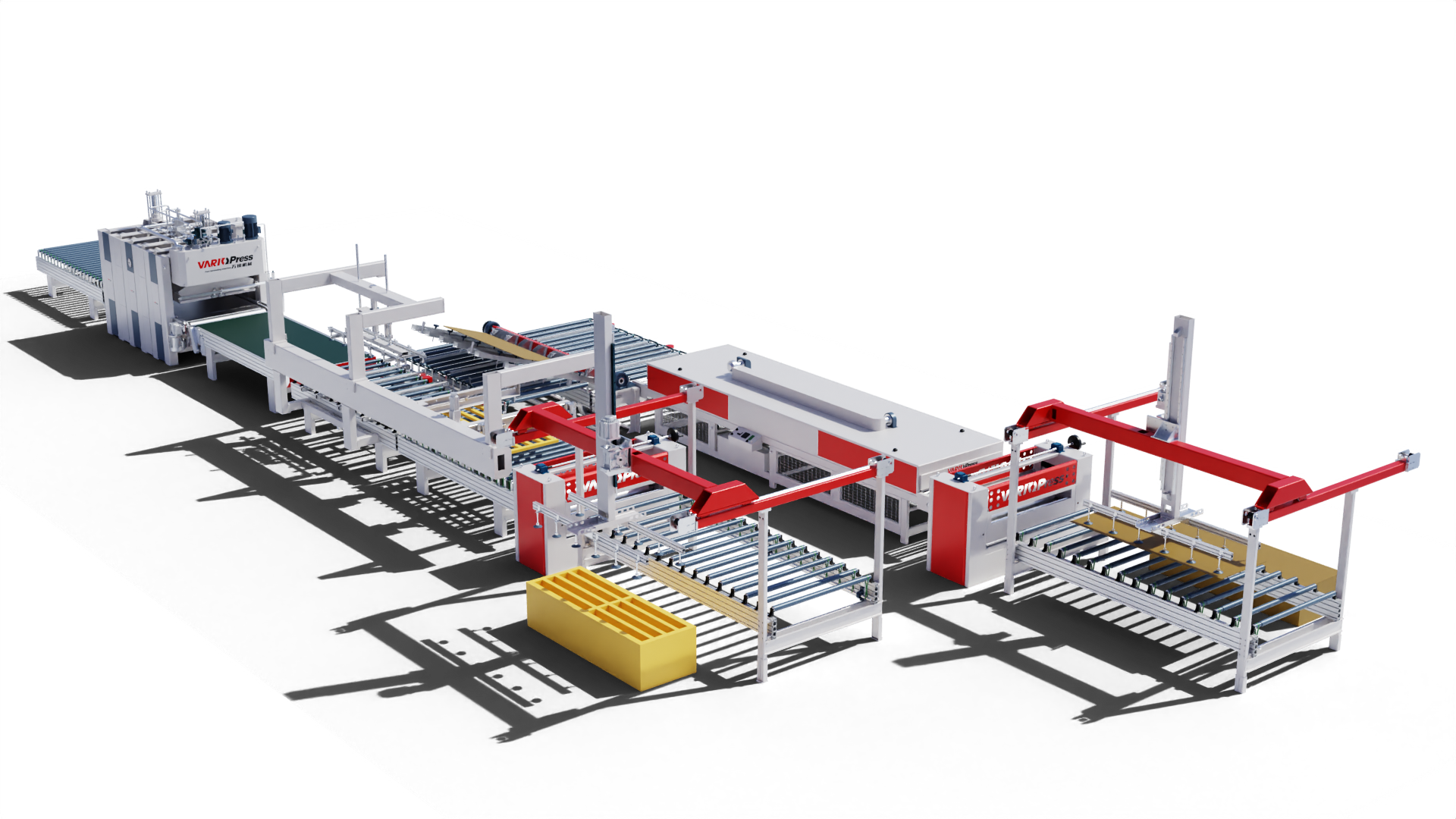

Automatic Flat Laminating Line

Heat-insulating broken-bridge aluminum alloy doors and windows are made of heat-insulating aluminum alloy profiles and related supporting materials combined and processed, while heat-insulating aluminum alloy profiles are composite profiles with heat-insulating function made of heat-insulating materials connected with aluminum alloy profiles.

Categories: By Mechanical Series

Products Detail

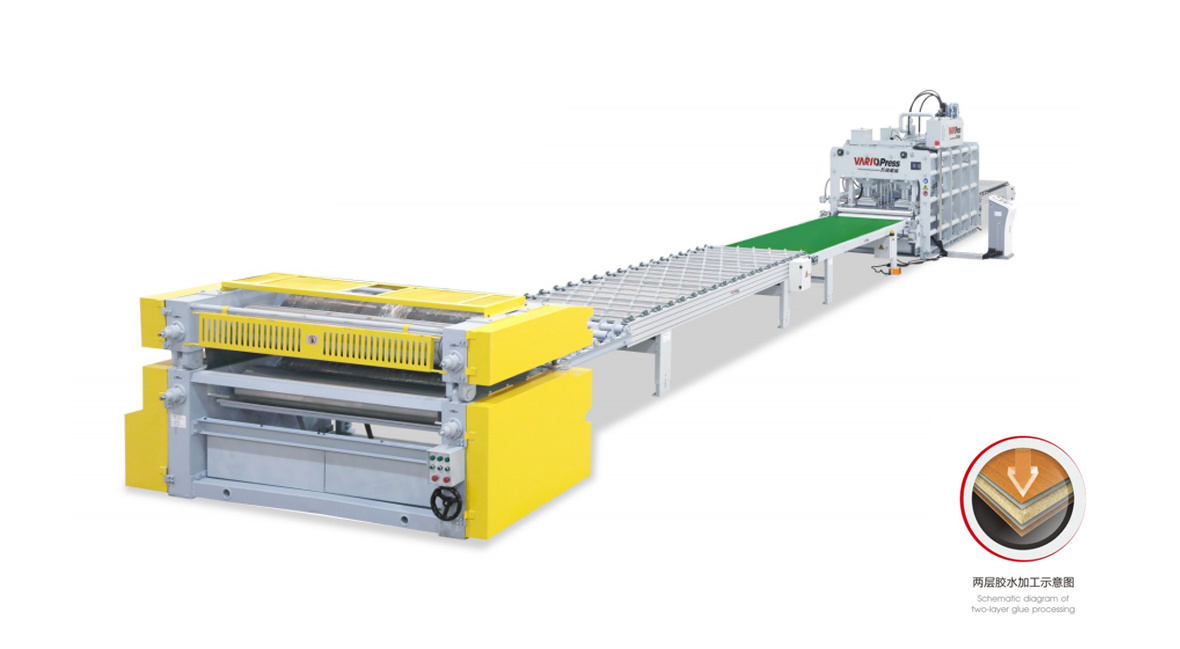

The Automatic Flat Laminating Line is a specialized production system designed for the efficient lamination of various materials onto flat surfaces. This advanced manufacturing line is equipped with automated processes and machinery to laminate materials such as wood veneer, decorative films, melamine paper, and PVC onto substrates like plywood, MDF (Medium-Density Fiberboard), particleboard, and other flat panels.

Key Features and Functions of the Automatic Flat Laminating Line include:

Material Handling: The production line includes material handling systems that efficiently feed and position the base panels and laminating materials for the lamination process. This ensures smooth and precise alignment of materials for uniform lamination.

Glue Application: The Automatic Flat Laminating Line is equipped with glue application units that evenly distribute adhesive onto the surface of the base panels or laminating materials. This helps secure the bond between the materials during the lamination process.

Lamination Process: The production line features heating and pressing units that apply heat and pressure to fuse the laminating materials onto the base panels. This process ensures a strong and durable bond, creating finished laminated panels with high-quality surface finishes.

Cooling and Trimming: After lamination, the panels pass through cooling units to stabilize the adhesive bond and ensure proper curing. Trimming stations may also be included in the production line to cut the laminated panels to the desired size and shape.

Quality Control: The Automatic Flat Laminating Line incorporates quality control measures such as inspection systems to check for any defects or imperfections in the laminated panels. Any issues identified can be addressed promptly to maintain the quality standards of the finished products.

Overall, the Automatic Flat Laminating Line plays a crucial role in the manufacturing of laminated panels used in furniture production, interior design, construction, and other industries. By automating the lamination process and ensuring precision and consistency in production, this advanced system enhances efficiency, quality, and productivity in the manufacturing of laminated panels.

From 2012 to today, Wanrui has been dealing with all kinds of wooden door enterprises for 10 years. 10 years, Wanrui has gone deep into the industry to understand the needs of wooden door enterprises; in the face of the problem of press-fit and press-stick in the production of wooden door enterprises, Wanrui Machinery has originally constructed the multiple perspectives of "face/people/efficiency/energy/fitting" to deal with the problem comprehensively. Now, Wanrui has served more than 4,000 wooden door enterprises, and has been praised by everyone!

Keywords:

Automatic Flat Laminating Line

Recommended Products