Select by application scenario

Select by Mechanical Series

CT8-01

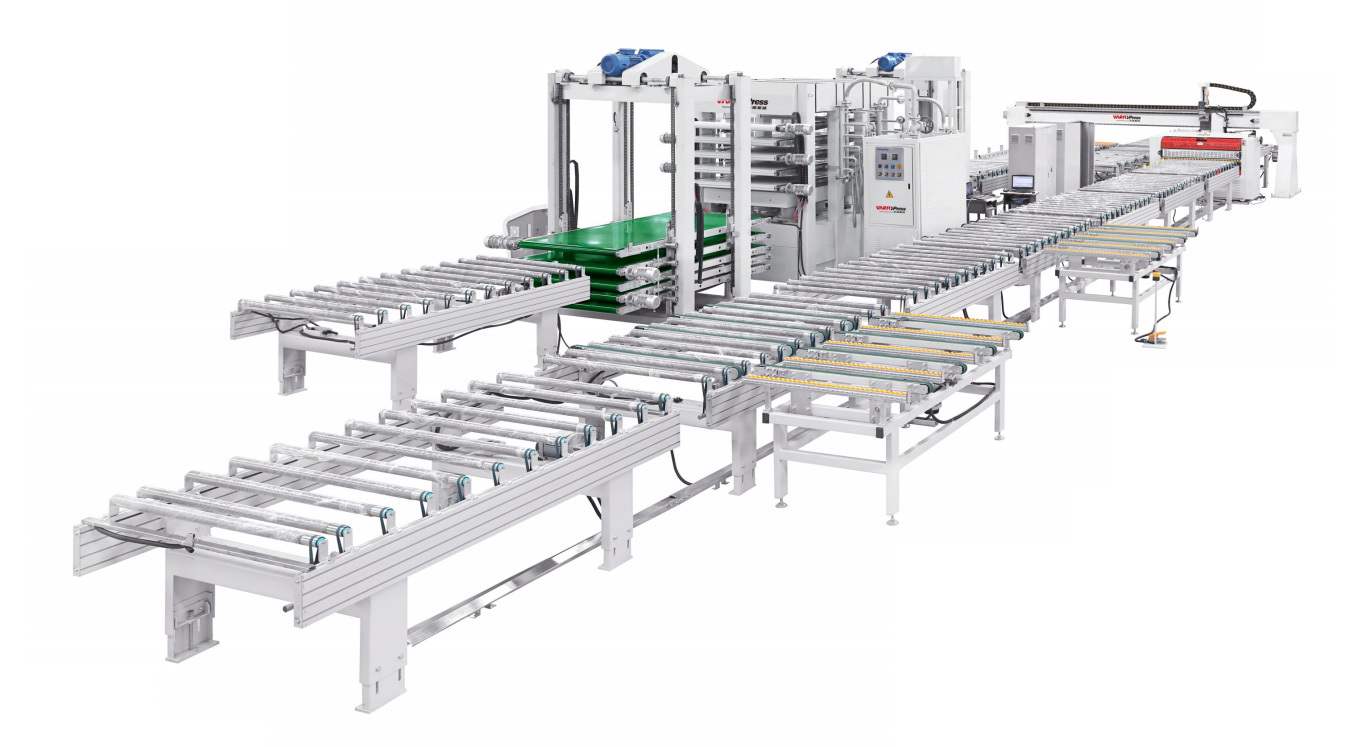

Paint-free door leaf cold-pressed composite production line

Heat-insulating broken-bridge aluminum alloy doors and windows are made of heat-insulating aluminum alloy profiles and related supporting materials combined and processed, while heat-insulating aluminum alloy profiles are composite profiles with heat-insulating function made of heat-insulating materials connected with aluminum alloy profiles.

Categories: CT Series

Products Detail

The Paint-free Door Leaf Cold-Pressed Composite Production Line is a revolutionary manufacturing system that transforms the traditional door production process. By eliminating the need for painting, this production line not only reduces the environmental burden but also enhances the efficiency and quality of door manufacturing.

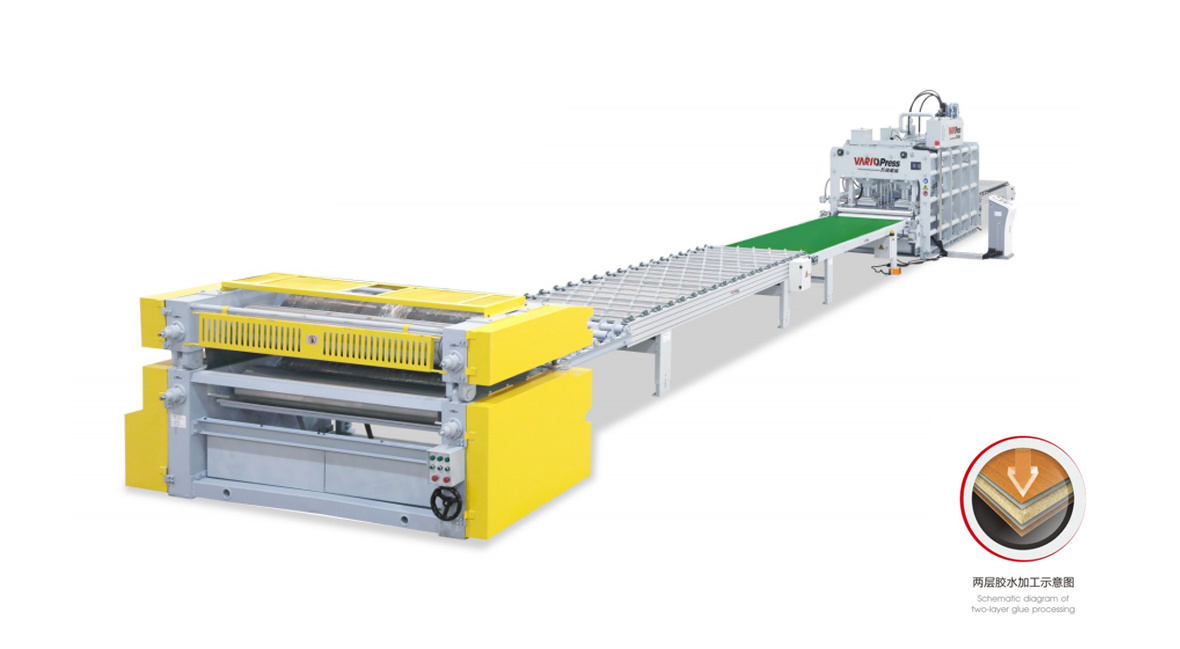

The cold-pressing technique employed in this production line is a key factor in its success. It involves the precise layering of composite materials under controlled conditions, resulting in door leaves that are strong, durable, and visually appealing. The absence of painting means that the natural beauty of the composite materials is preserved, creating a sleek and modern look.

The production line is designed for high-volume, continuous production. Automation and precision engineering ensure that each door leaf is manufactured to the highest standards, with minimal waste and maximum efficiency. This not only reduces costs but also allows for faster turnaround times, meeting the demands of today’s fast-paced market.

Moreover, the Paint-free Door Leaf Cold-Pressed Composite Production Line offers great flexibility in terms of customization. Manufacturers can easily adjust the materials, colors, and finishes to meet the specific requirements of their customers. This versatility makes it an ideal choice for door manufacturers who want to offer a wide range of products without compromising on quality or sustainability.

In conclusion, the Paint-free Door Leaf Cold-Pressed Composite Production Line is a game-changer in the door manufacturing industry. It combines efficiency, quality, and sustainability, enabling manufacturers to create high-performance, paint-free door leaves that are both visually appealing and environmentally friendly.

| Product Model | CT5-08 | CT6-08 | CT6-01 | CT8-01 |

| Capacity output | 300 sets/8 hours 1 fan/60s | 500 sets/8 hours 1 fan/60s | 500 sets/8 hours 1 fan/60s | 600 sets/8 hours 1 fan/60s |

| Stavisioning | 4 people | 1 person | 4 people | 4 people |

| Glue process | Ordinary white glue | Ordinary white glue | Ordinary white glue | Ordinary white glue |

| Pressing time | 4-6 hours | 4-6 hours | 4-6 hours | 4-6 hours |

| Total length of production line | 43 m | 25 m | 21 m | 31 m |

From 2012 to today, Wanrui has been dealing with all kinds of wooden door enterprises for 10 years. 10 years, Wanrui has gone deep into the industry to understand the needs of wooden door enterprises; in the face of the problem of press-fit and press-stick in the production of wooden door enterprises, Wanrui Machinery has originally constructed the multiple perspectives of "face/people/efficiency/energy/fitting" to deal with the problem comprehensively. Now, Wanrui has served more than 4,000 wooden door enterprises, and has been praised by everyone!

Keywords:

Paint-free door leaf cold-pressed composite production line

Recommended Products