Select by application scenario

Select by Mechanical Series

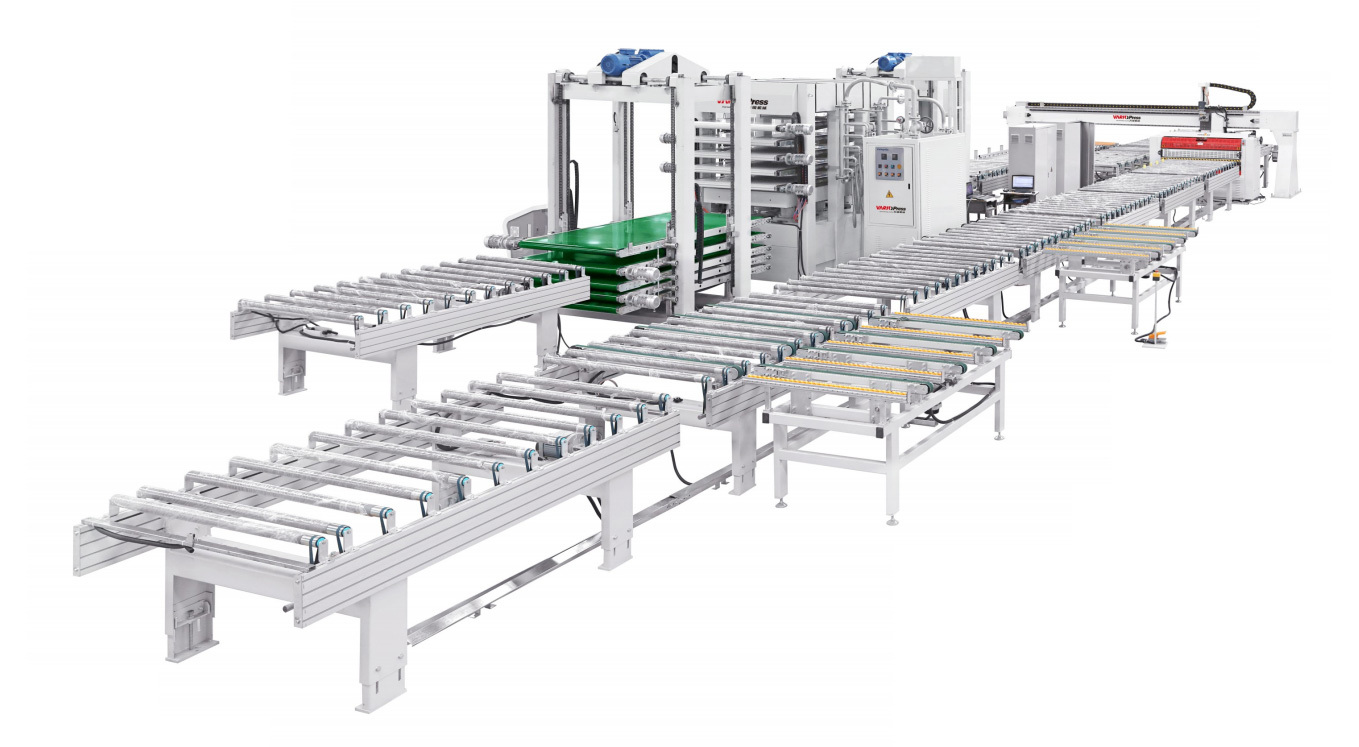

Non-standard customized hot press

Heat-insulating broken-bridge aluminum alloy doors and windows are made of heat-insulating aluminum alloy profiles and related supporting materials combined and processed, while heat-insulating aluminum alloy profiles are composite profiles with heat-insulating function made of heat-insulating materials connected with aluminum alloy profiles.

Categories: VP Series

Products Detail

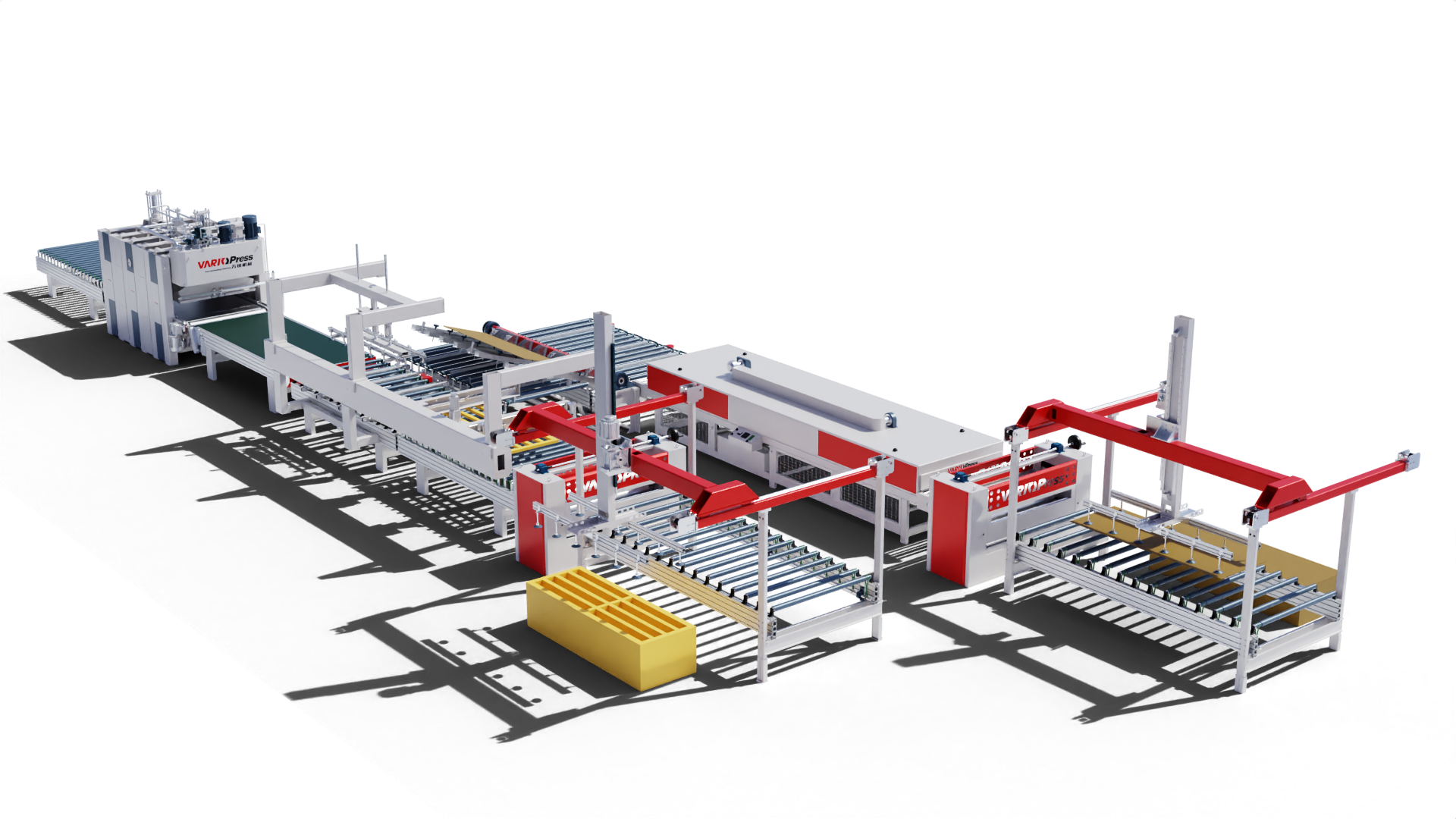

The non-standard customized hot press is a specialized piece of equipment tailored to meet unique manufacturing or processing requirements that do not fit within the parameters of standard, off-the-shelf presses. This type of machinery is designed and built specifically for a given application, incorporating unique features and capabilities that are not available in standard models.

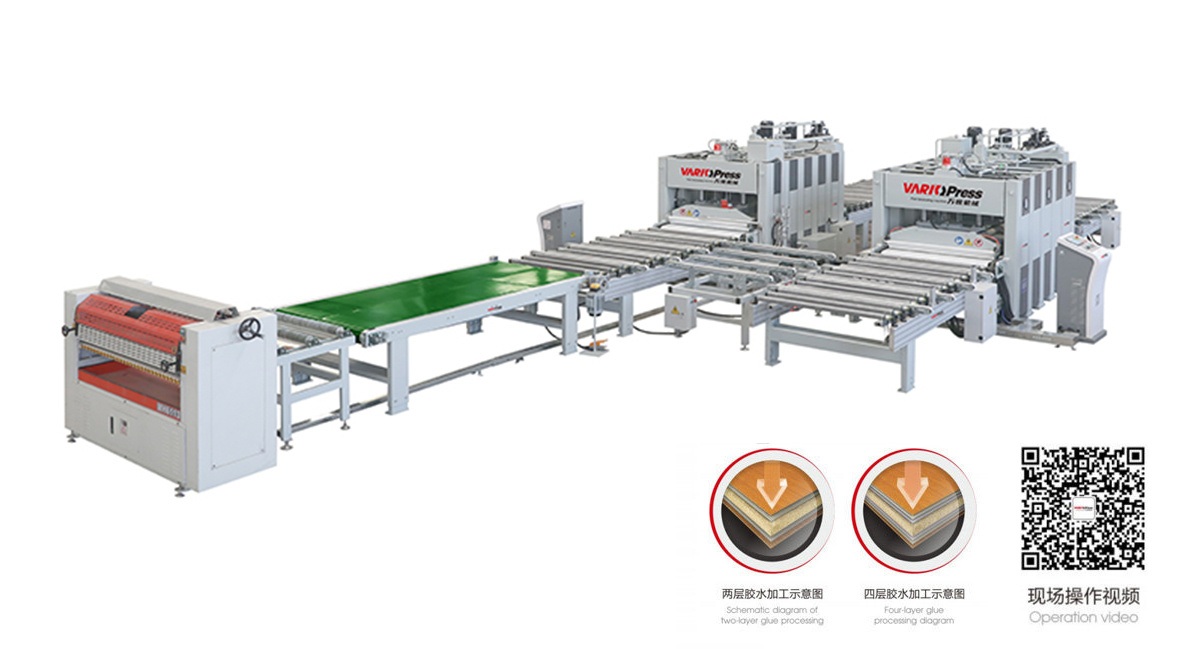

The customization aspect of non-standard hot presses allows for a wide range of configurations, sizes, and capabilities. Whether it's the size of the platen, the temperature range, the pressure applied, or the automation level, these presses can be tailored to suit the exact needs of the user. This flexibility ensures that the hot press is optimized for the specific material being processed, the desired outcome, and the production environment.

One of the key benefits of non-standard customized hot presses is their ability to handle complex processes with precision and efficiency. Whether it's laminating, bonding, curing, or another type of thermal process, these presses can be configured to deliver the desired results with minimal waste and maximum throughput. The use of advanced materials and precision engineering ensures that the presses operate smoothly and reliably, even under demanding conditions.

Moreover, non-standard customized hot presses often incorporate features that enhance safety and ergonomics. This includes safety guards, emergency stop buttons, and ergonomic designs that minimize operator fatigue. By prioritizing the safety and comfort of operators, these presses contribute to a safer and more productive work environment.

In summary, non-standard customized hot presses are an essential tool for manufacturers and processors who require specialized solutions for their unique production needs. Their customizability, precision, and efficiency make them a valuable addition to any advanced manufacturing operation.

Experience the future of woodworking with our Automated Woodworking Machinery. Combining precision engineering with advanced automation, our machinery streamlines production processes for unparalleled efficiency and quality. From CNC routers to edgebanders, our comprehensive lineup offers solutions for every woodworking application. Elevate your productivity and craftsmanship with our Automated Woodworking Machinery.

| Machine Model | MY216*8/16(3)H1RC | MY215*12/16(3)H1RC |

| Nominal total pressure | 1600kN | 1600kN |

| Number of working layers | Layer 3 | Layer 3 |

| Quantity and specification of hot press plate | 4-2500*2000*42mm | 4-3600*1500*42mm |

| Hot press plate spacing | 150mm | 120mm |

| Unit surface pressure | 3.2kgf/cm2 | 3kgf/cm2 |

| Quantity and diameter of oil cylinder | 10-Ø85mm | 12-Ø85mm |

| Installed power | 77.5kW | 77.5kW |

| Heating mode and medium | electric heating medium circulation | electric heating medium circulation |

From 2012 to today, Wanrui has been dealing with all kinds of wooden door enterprises for 10 years. 10 years, Wanrui has gone deep into the industry to understand the needs of wooden door enterprises; in the face of the problem of press-fit and press-stick in the production of wooden door enterprises, Wanrui Machinery has originally constructed the multiple perspectives of "face/people/efficiency/energy/fitting" to deal with the problem comprehensively. Now, Wanrui has served more than 4,000 wooden door enterprises, and has been praised by everyone!

Keywords:

Non-standard customized hot press

Recommended Products