Select by application scenario

Select by Mechanical Series

MT5-08

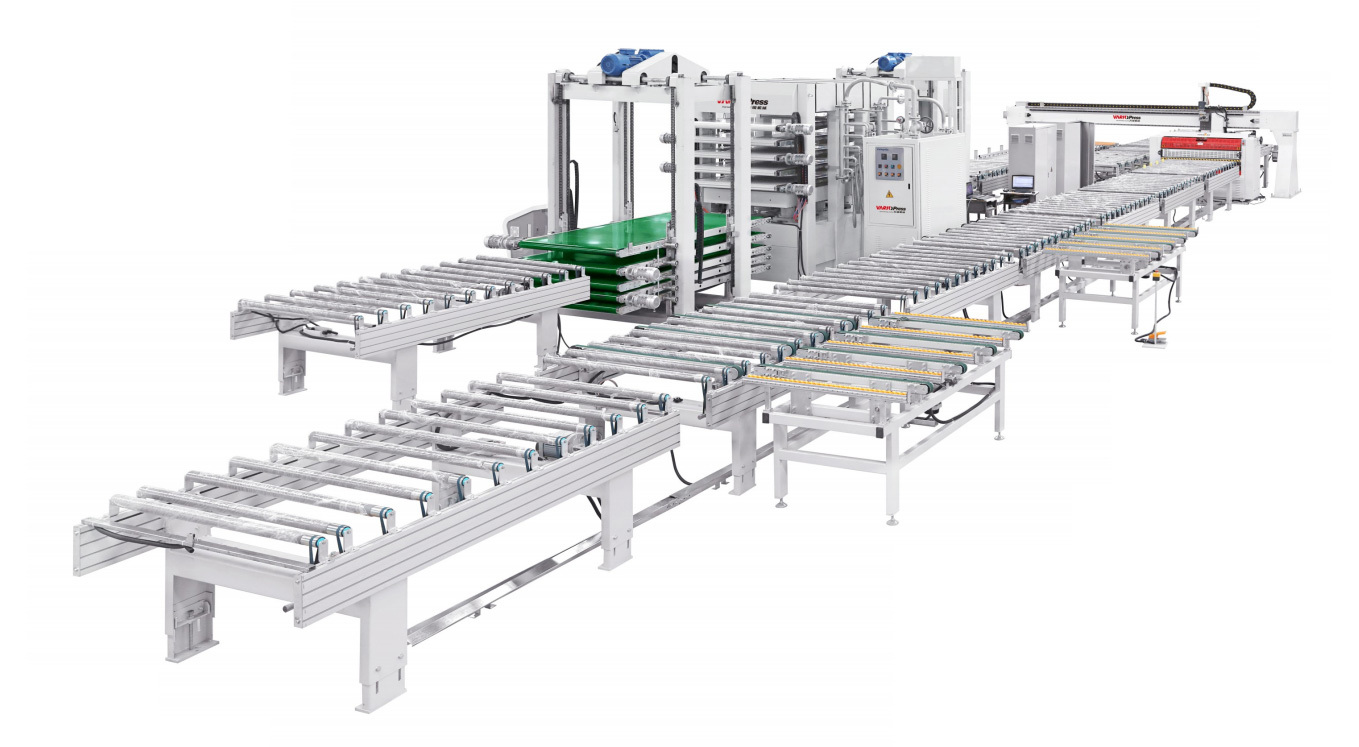

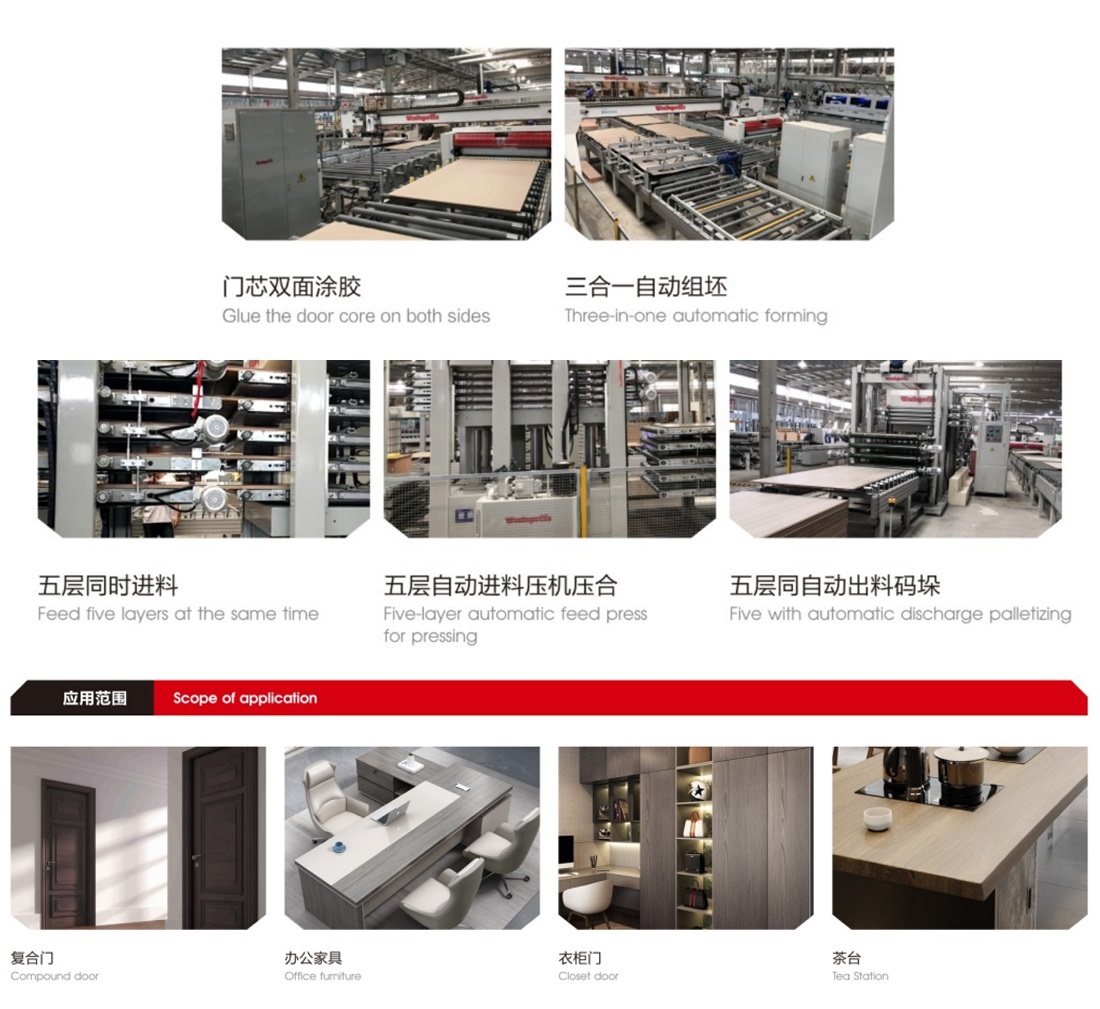

Five-layer wooden door rapid cold pressing composite production line

Heat-insulating broken-bridge aluminum alloy doors and windows are made of heat-insulating aluminum alloy profiles and related supporting materials combined and processed, while heat-insulating aluminum alloy profiles are composite profiles with heat-insulating function made of heat-insulating materials connected with aluminum alloy profiles.

Categories: MT Series

Products Detail

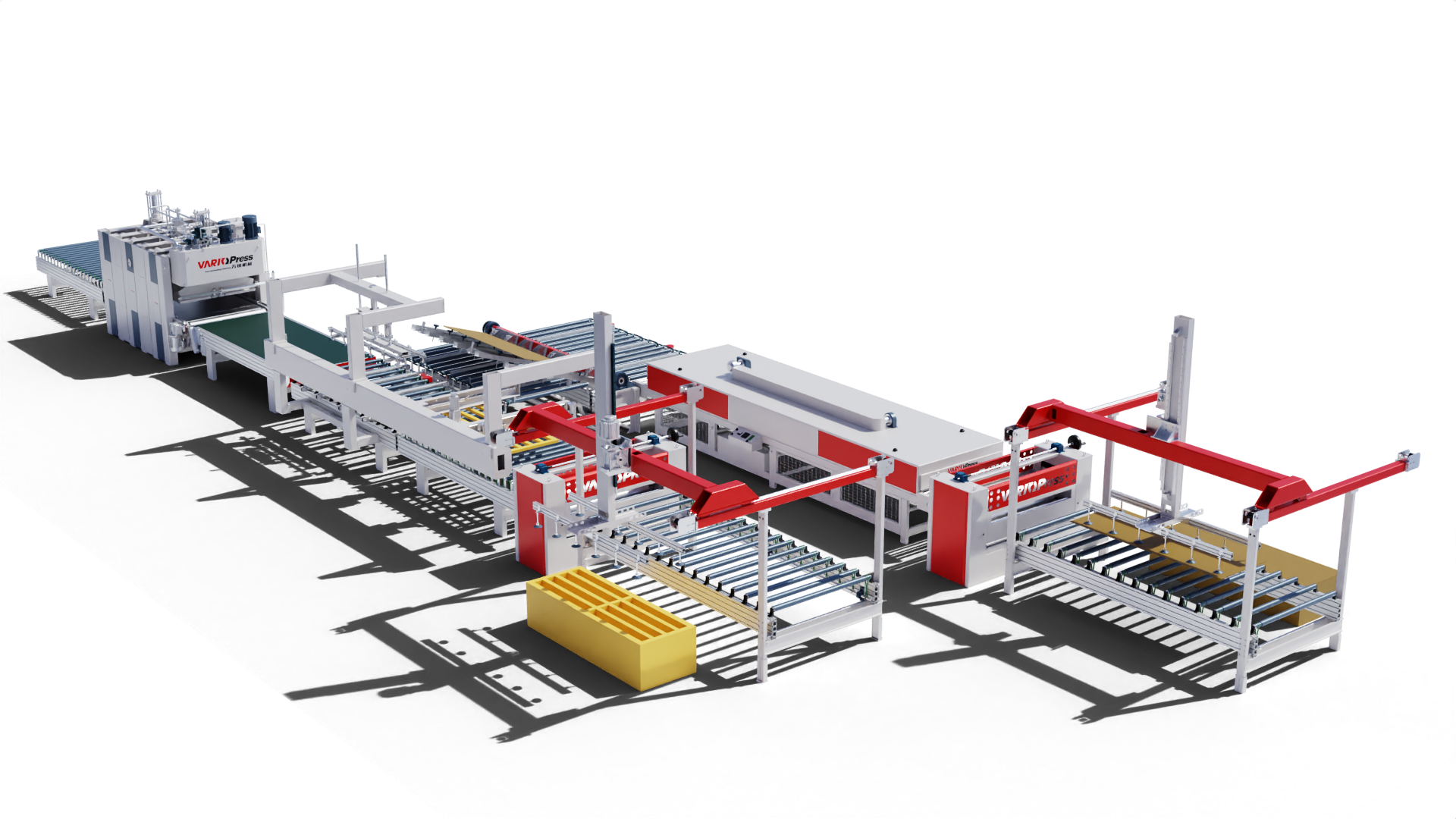

The Five-Layer Wooden Door Rapid Cold Pressing Composite Production Line is a cutting-edge manufacturing solution designed to streamline the production process of high-quality wooden doors. This advanced production line combines innovative technology, precision engineering, and automation to enhance efficiency, quality, and throughput in the production of five-layer wooden doors. Let’s explore the key features and benefits of this state-of-the-art composite production line:

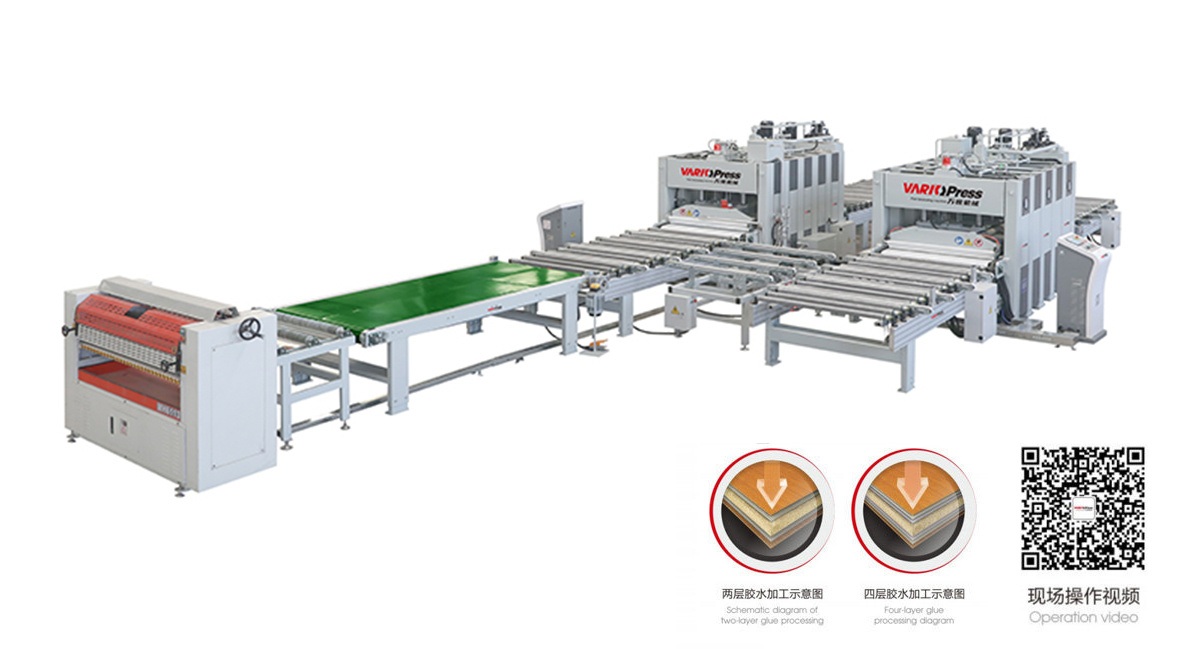

Advanced Composite Technology: The Five-Layer Wooden Door Rapid Cold Pressing Composite Production Line utilizes advanced composite technology to bond multiple layers of wood materials together seamlessly. By applying precise pressure, temperature, and pressing parameters, this technology ensures a strong and durable bond between the layers, resulting in a structurally sound wooden door with enhanced strength and stability.

High-Speed Production: This production line is designed for rapid and continuous operation, allowing manufacturers to achieve high production speeds and meet tight deadlines. The automated processes, quick cycle times, and efficient material handling systems enable fast and efficient production of five-layer wooden doors, increasing overall manufacturing output.

Customization Capabilities: The production line offers flexibility and customization options to meet diverse design requirements and customer preferences. Manufacturers can easily adjust the parameters for each production run, allowing for the creation of unique and tailored wooden doors with different sizes, shapes, finishes, and configurations to cater to a wide range of market needs.

Quality Assurance: With precise control over the pressing process and composite bonding, the production line ensures consistent quality and accuracy in the manufacturing of five-layer wooden doors. The system minimizes errors, defects, and variations in the final product, resulting in high-quality finishes, smooth surfaces, and precise dimensions that meet industry standards and customer expectations.

Operational Efficiency: The automated features and the seamless integration of components in the production line enhance operational efficiency and reduce labor costs. The optimized workflow, minimal downtime, and ease of maintenance contribute to a streamlined production process, allowing manufacturers to maximize their productivity and profitability in the manufacturing of wooden doors.

Sustainable Practices: The Five-Layer Wooden Door Rapid Cold Pressing Composite Production Line promotes sustainability by minimizing material waste, energy consumption, and environmental impact. The efficient use of resources, the reduction of pollutants, and the adoption of eco-friendly practices contribute to a more sustainable and responsible manufacturing process in the woodworking industry.

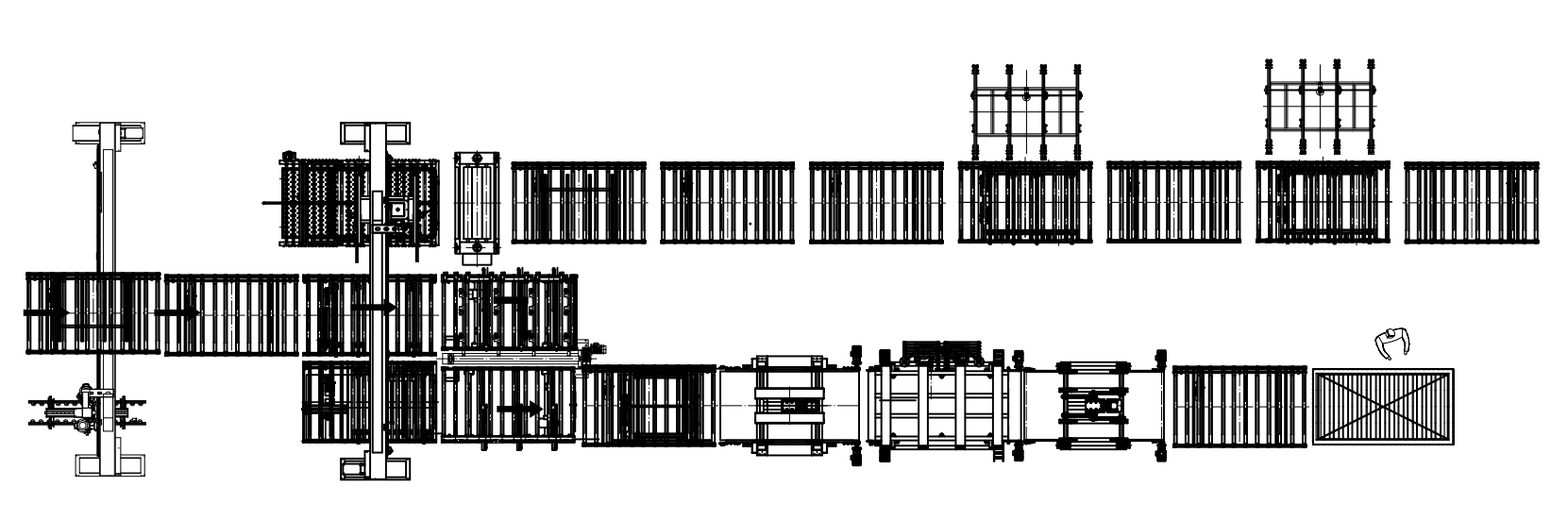

| Product Model | MT5-01 | MT5-02 | MT5-03 | MT5-08 |

| Capacity output | 400 sets/8h 1 fan/60s | 500 sets/8h 1 fan/60s | 500 sets/8h 1 fan/60s | 600 sets/8h 1 fan/60s |

| Staunching | 4 people | 2 people | 1 person | 1 person |

| Glue process | One-component cold-pressed quick-drying adhesive | One-component cold-pressed quick-drying adhesive | One-component cold-pressed quick-drying adhesive | One-component cold-pressed quick-drying adhesive |

| Pressing time | 5 minutes at room temperature | 5 minutes at room temperature | 5 minutes at room temperature | 5 minutes at room temperature |

| Installed power | 28.45kw | 38.4kw | 56.96kw | 62kw |

| Total length of production line | 15m | 21m | 28.5m | 31m |

From 2012 to today, Wanrui has been dealing with all kinds of wooden door enterprises for 10 years. 10 years, Wanrui has gone deep into the industry to understand the needs of wooden door enterprises; in the face of the problem of press-fit and press-stick in the production of wooden door enterprises, Wanrui Machinery has originally constructed the multiple perspectives of "face/people/efficiency/energy/fitting" to deal with the problem comprehensively. Now, Wanrui has served more than 4,000 wooden door enterprises, and has been praised by everyone!

Keywords:

Five-layer wooden door rapid cold pressing composite production line

Recommended Products