newest Wood veneer automatic veneer production line

Time: 2024-11-13

Wood veneer is a popular material used in various industries for its aesthetic appeal and versatility. To meet the growing demand for high-quality wood veneer sheets, manufacturers are turning to advanced production technologies like the Wood Veneer Automatic Veneer Production Line.

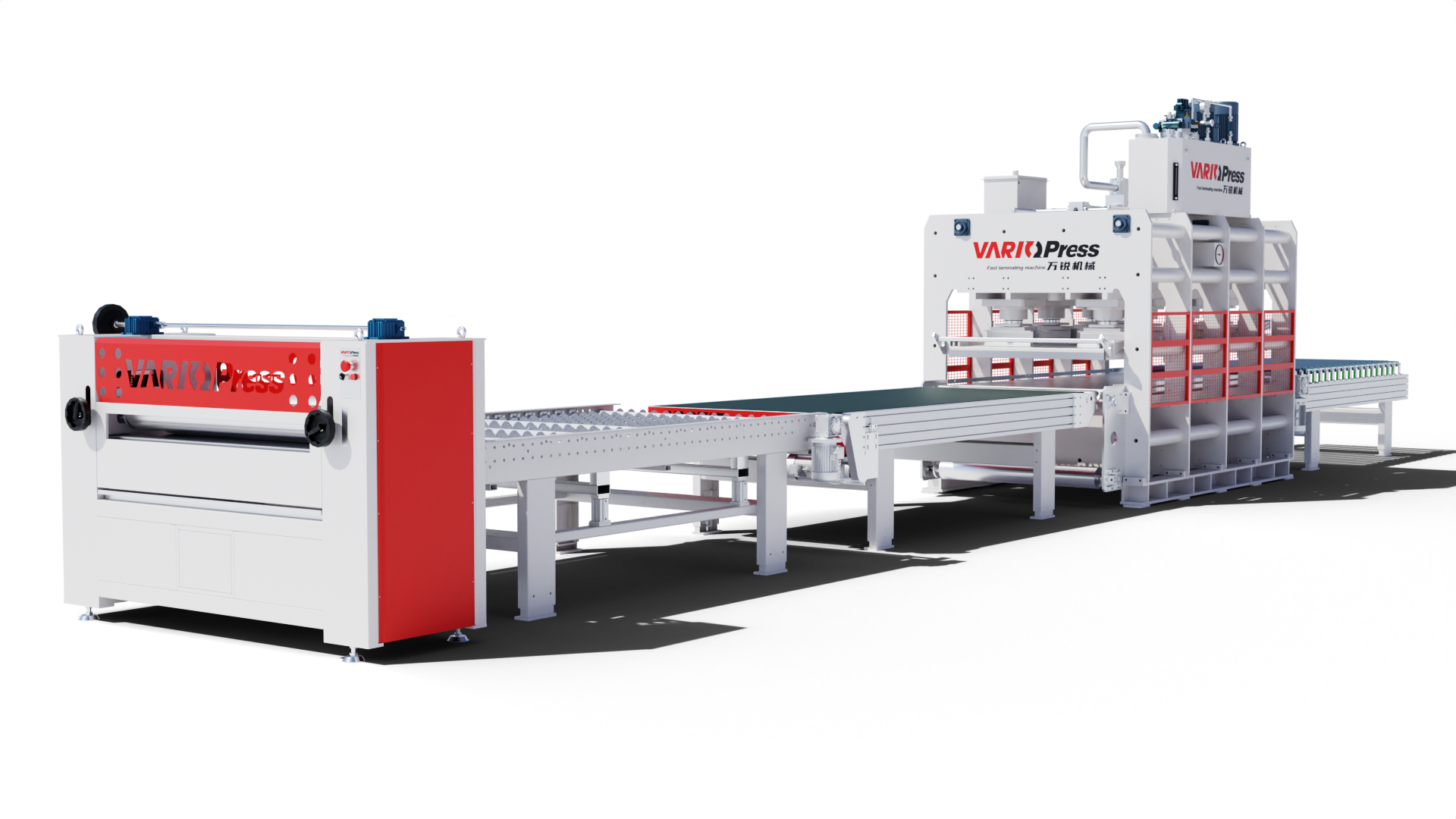

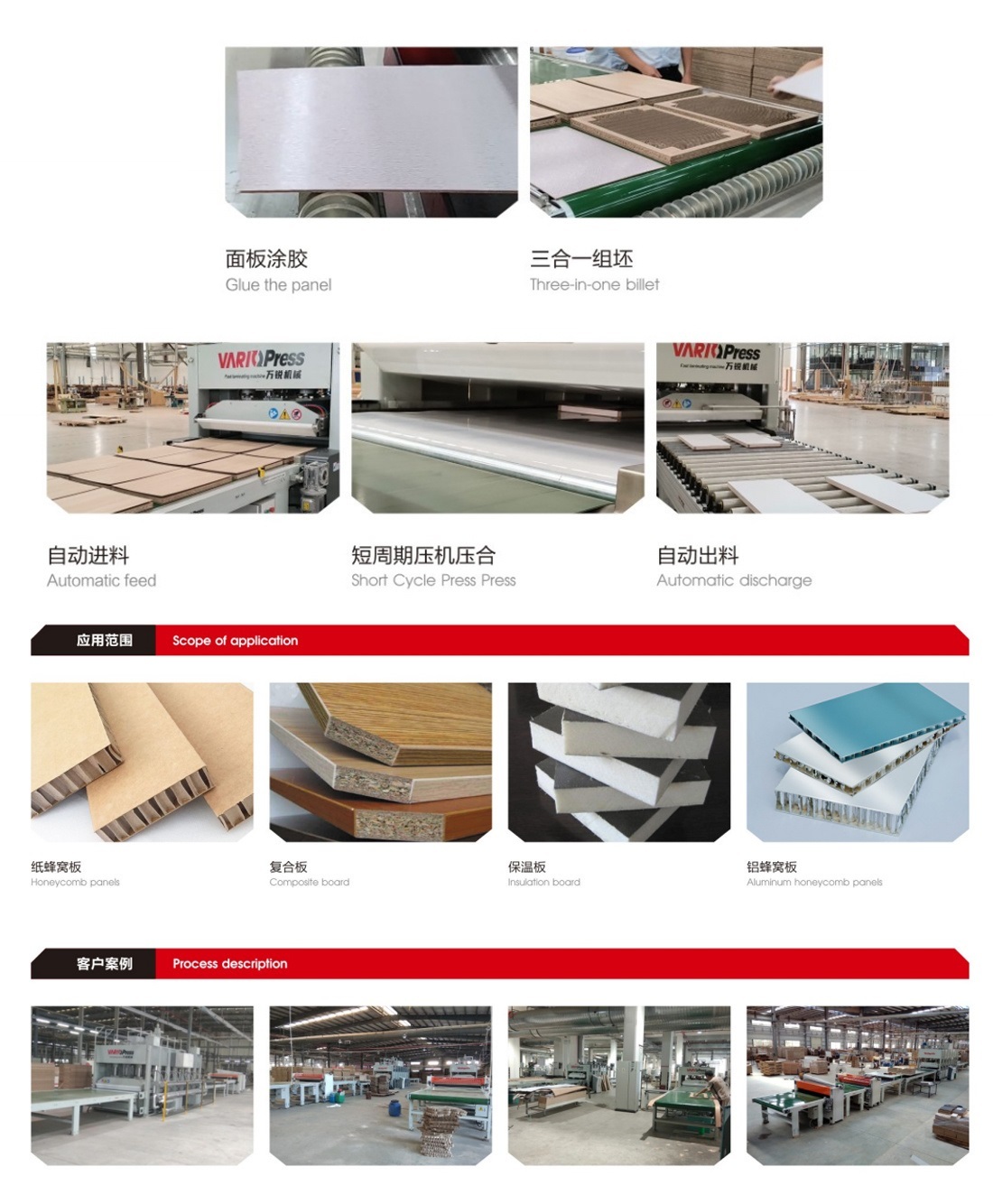

This state-of-the-art production line is revolutionizing the manufacturing process of wood veneer sheets by incorporating automated processes and machinery. With features such as precise cutting and peeling units, efficient drying and conditioning systems, and thorough inspection stations, the production line ensures consistent quality and uniformity in the veneer sheets produced.

One of the key advantages of the Wood Veneer Automatic Veneer Production Line is its ability to enhance efficiency and productivity in manufacturing operations. By automating repetitive tasks and streamlining production processes, manufacturers can significantly increase their output while maintaining high standards of quality.

Furthermore, the production line’s advanced technology allows for greater customization and flexibility in producing wood veneer sheets of different sizes, thicknesses, and finishes. This not only caters to the diverse requirements of customers but also opens up opportunities for innovative design possibilities in various industries.

In conclusion, the Wood Veneer Automatic Veneer Production Line represents a significant advancement in wood veneer manufacturing, offering improved efficiency, quality, and customization capabilities. As manufacturers continue to adopt such cutting-edge technologies, the wood veneer industry is poised for further growth and innovation in the coming years.

| Product Model | DT1-01-3 | DT1-01-5 | DT3-01 | DT5-08 |

| Capacity output | 180 fans/8 hours | 300 fans/8 hours | 500 fans/8 hours | 800 fans/8 hours |

| Staunching | 2 people | 2 people | 2 people | 2 people |

| Glue process | One-component cold-pressed quick-drying adhesive | One-component cold-pressed quick-drying adhesive | One-component cold-pressed quick-drying adhesive | PVAC latex |

| Pressing time | 3 minutes | 3 minutes | 3 minutes | 3 minutes |

| Installed power | 57.75kw | 83.1kw | 88.2kw | 177.7kw |

| Total length of production line | 14m | 20m | 25m | 21m |