PRODUCTS CENTER

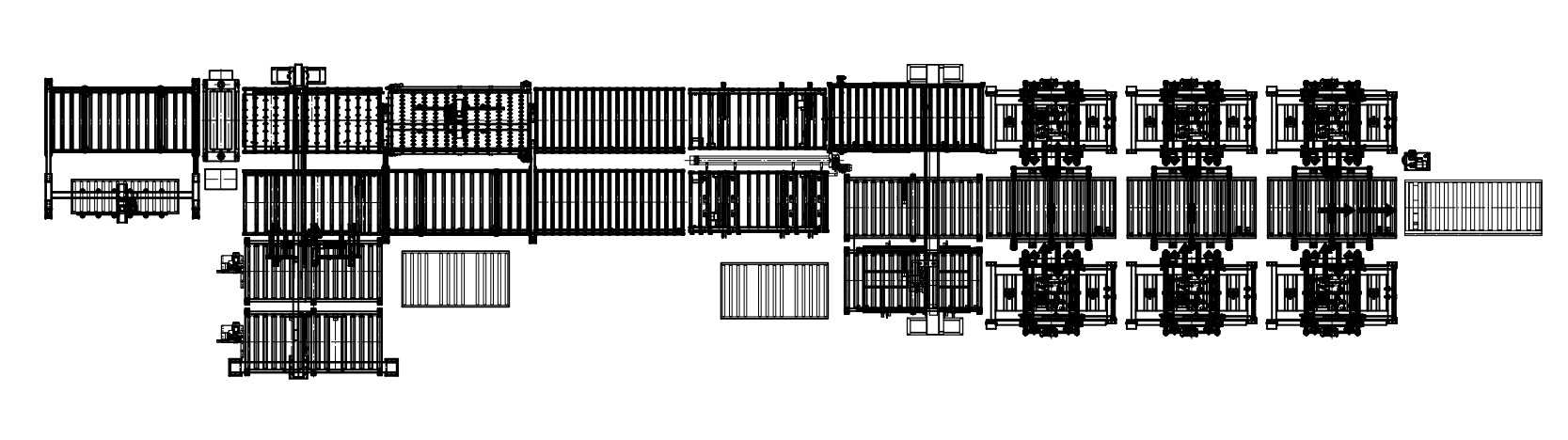

Papua New Guinea Paint-free door leaf cold-pressed composite production line

Category:

Product Description

The Paint-free Door Leaf Cold-Pressed Composite Production Line represents a significant innovation in the manufacturing of doors, offering a sustainable and efficient alternative to traditional painting processes. This advanced production line specializes in the creation of door leaves made from cold-pressed composite materials, eliminating the need for painting, thus reducing environmental impact and production time.

The core of this production line lies in its cold-pressing technology. Composite materials are carefully selected and layered, then pressed under controlled conditions to achieve the desired density and strength. This process ensures that the door leaves are durable, stable, and free from the need for surface painting.

What’s more, the Paint-free Door Leaf Cold-Pressed Composite Production Line incorporates state-of-the-art automation and precision engineering. This allows for continuous and efficient production, minimizing waste and maximizing output. The resulting door leaves not only possess excellent physical properties but also exhibit a sleek and modern aesthetic, making them highly desirable in today’s market.

In addition to its environmental and efficiency benefits, the production line also offers flexibility in terms of customization. Different materials, colors, and finishes can be easily integrated into the production process, enabling manufacturers to meet a wide range of customer demands.

In summary, the Paint-free Door Leaf Cold-Pressed Composite Production Line offers a cutting-edge solution for door manufacturers looking to improve their production processes, reduce environmental impact, and create high-quality, paint-free door leaves.

| Product Model | CT5-08 | CT6-08 | CT6-01 | CT8-01 |

| Capacity output | 300 sets/8 hours 1 fan/60s | 500 sets/8 hours 1 fan/60s | 500 sets/8 hours 1 fan/60s | 600 sets/8 hours 1 fan/60s |

| Stafting | 4 people | 1 person | 4 people | 4 people |

| Glue process | Ordinary white glue | Ordinary white glue | Ordinary white glue | Ordinary white glue |

| Pressing time | 4-6 hours | 4-6 hours | 4-6 hours | 4-6 hours |

| Total length of production line | 43 m | 25 m | 21 m | 31 m |