best Wood veneer automatic veneer production line

Time: 2024-11-13

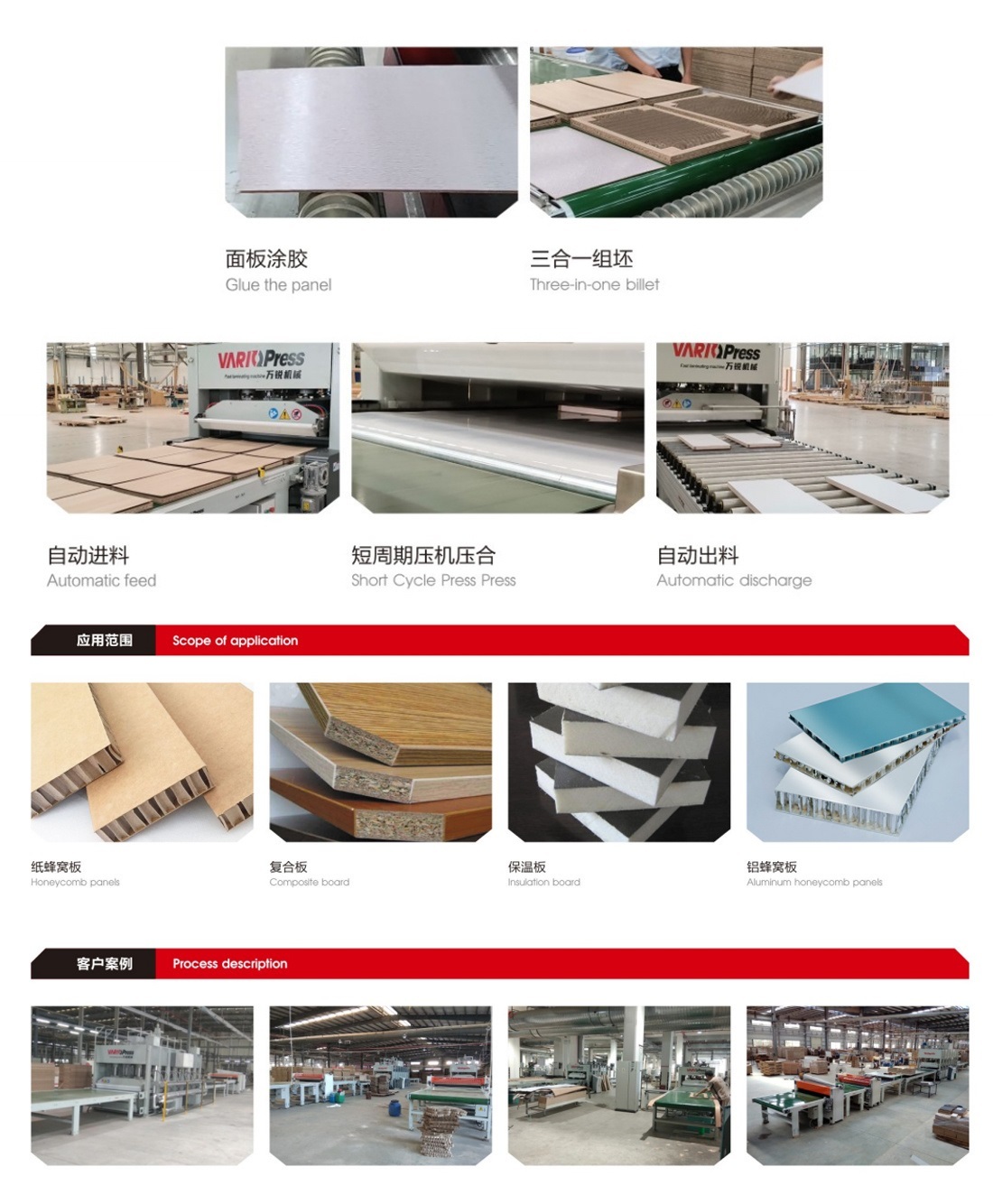

Our Wood Veneer Automatic Veneer Production Line is a cutting-edge solution for efficient and high-quality wood veneer production. Designed to streamline the manufacturing process and enhance productivity, this state-of-the-art system is perfect for woodworking businesses looking to optimize their operations.

Key Features:

Automated Operation: The production line is fully automated, minimizing manual labor and ensuring consistent quality throughout the manufacturing process. From feeding the raw materials to cutting and finishing the veneer, every step is seamlessly integrated for maximum efficiency.

Precision Cutting: Equipped with advanced cutting technology, our production line ensures precise and accurate cutting of wood veneer sheets. This results in uniform thickness, smooth surfaces, and minimal waste, ultimately improving the overall product quality.

Customization Options: Our Wood Veneer Automatic Veneer Production Line offers customization options to meet the unique needs of different woodworking projects. Whether you need specific veneer sizes, shapes, or finishes, our system can be tailored to deliver the desired results.

Energy-Efficient Design: The production line is designed to maximize energy efficiency and reduce operating costs. By incorporating eco-friendly practices and energy-saving components, our system helps businesses lower their environmental footprint while saving on utility expenses.

User-Friendly Interface: With a user-friendly interface and intuitive controls, our production line is easy to operate and requires minimal training. This allows operators to quickly adapt to the system and maintain smooth operations without unnecessary downtime.

Overall, our Wood Veneer Automatic Veneer Production Line offers a comprehensive solution for wood veneer manufacturing, combining cutting-edge technology with cost-effective production methods. Experience increased efficiency, improved quality, and enhanced productivity with our innovative system.

| Product Model | DT1-01-3 | DT1-01-5 | DT3-01 | DT5-08 |

| Capacity output | 180 fans/8 hours | 300 fans/8 hours | 500 fans/8 hours | 800 fans/8 hours |

| Staunching | 2 people | 4 people | 2 people | 2 people |

| Glue process | One-component cold-pressed quick-drying adhesive | One-component cold-pressed quick-drying adhesive | One-component cold-pressed quick-drying adhesive | PVAC latex |

| Pressing time | 3 minutes | 3 minutes | 3 minutes | 3 minutes |

| Installed power | 57.75kw | 83.1kw | 88.2kw | 177.7kw |

| Total length of production line | 14m | 20m | 25m | 21m |