Woodworking Hot Press Machine

Time: 2024-11-13

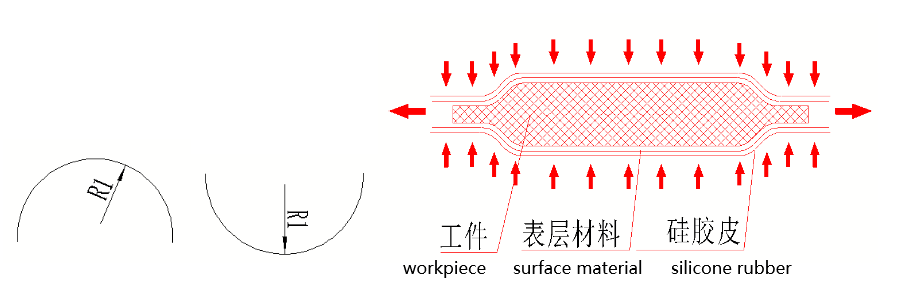

The wood skin curved surface positive and negative press is a kind of pressing equipment specially used for wood skin pressing and curved surface pressing. It adopts the technology of positive and negative pressure curved surface, which can quickly and accurately attach the wood skin to the curved surface material.

This technology solves the long-standing problems of wood skin surface pressing for a long time, artificial complexity, and wood skin bulging and falling off.

Wood surface positive and negative press is widely used in furniture manufacturing, interior decoration and other industries. It can not only improve production efficiency, but also ensure the quality and beauty of products.

In short, the wood skin curved surface positive and negative press is an advanced equipment with efficient and accurate wood skin pressing and curved surface pressing functions. It will bring users higher work efficiency and better fit effect, and inject new vitality into the development of the wood skin pressure industry.

Discover precision and reliability with our Woodworking Hot Press Machine. Engineered for seamless operation, this cutting-edge equipment delivers uniform heat and pressure for efficient wood lamination and bonding. With advanced features and robust construction, our hot press machine ensures consistent results and superior quality in woodworking applications. Experience enhanced productivity and craftsmanship with our Woodworking Hot Press Machine.

Specification requirements of the workpiece:

A.0.45 ~ 0.6mm thick wood skin (≤0.6mm natural wood skin/with non-woven wood skin below wood skin can be)

B. the yin angle and the yang angle are greater than or equal to 60

Yang angle Yin angle