Short Cycle Veneer Automatic Production Line

Time: 2024-11-13

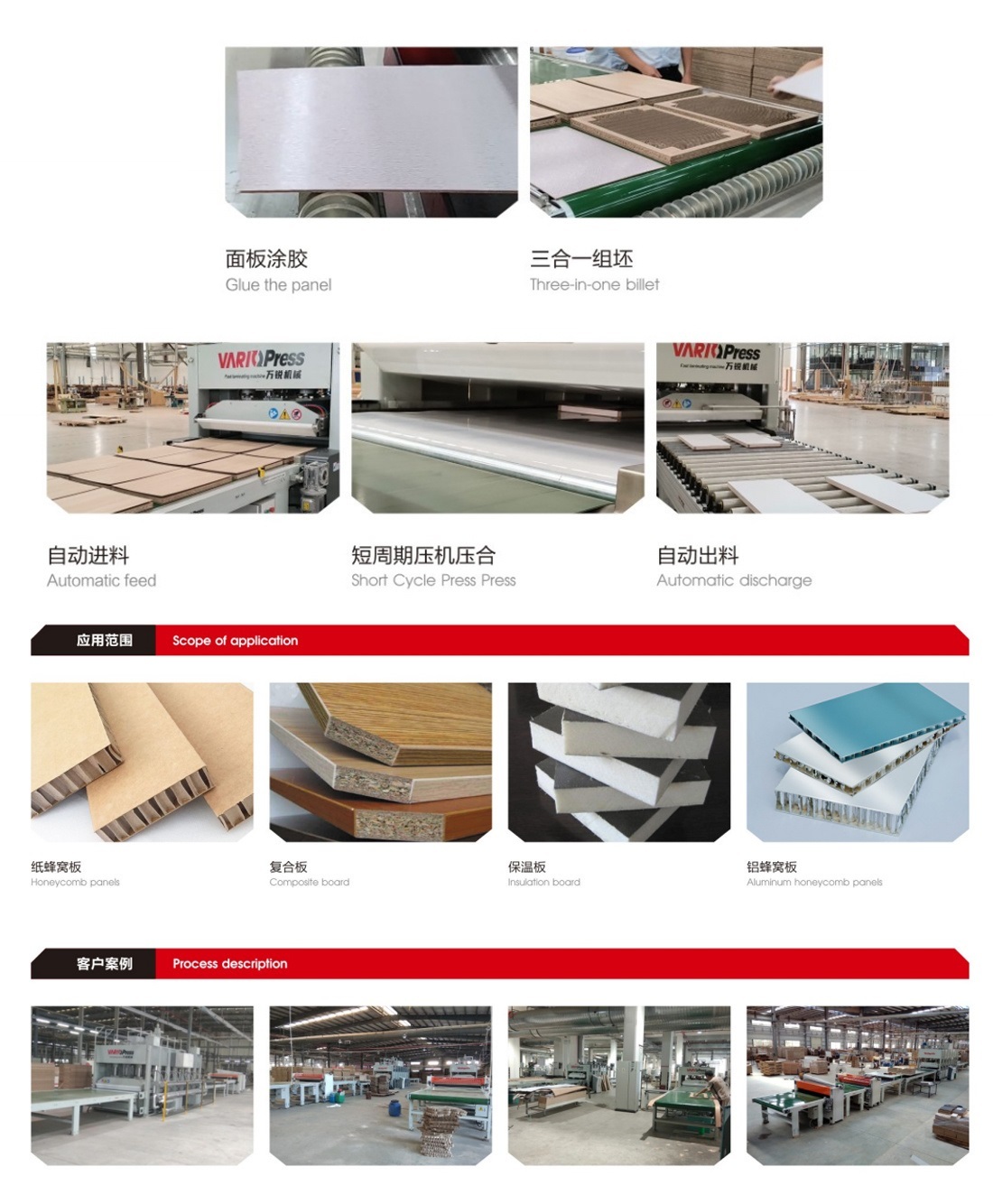

Introducing our Short Cycle Veneer Automatic Production Line, a groundbreaking solution revolutionizing veneer production. This state-of-the-art machinery is meticulously engineered to streamline the entire production process, from veneer preparation to finishing, ensuring unmatched efficiency and quality.

At the core of our production line is advanced automation technology, which seamlessly integrates each stage of the manufacturing process. From veneer cutting and drying to gluing and pressing, every step is optimized for maximum precision and consistency.

Versatility is a hallmark feature of our production line. It can accommodate various veneer sizes, thicknesses, and wood species, catering to diverse customer requirements. With customizable settings and programmable controls, manufacturers have the flexibility to tailor the production process to their specific needs.

| Production line model | MT1-01-3 | MT1-01-5 | MT1-01-6 | MT1-08 |

| Capacity output | 300 sets/8 hours | 300 sets/8 hours | 300 sets/8 hours | 300 sets/8 hours |

| Staunching | 2 people | 2 people | 2 people | 1 person |

| Glue process | Two-component cold-pressed quick-drying adhesive | Two-component cold-pressed quick-drying adhesive | Two-component cold-pressed quick-drying adhesive | Two-component cold-pressed quick-drying adhesive |

| Pressing time | 60-90 seconds at room temperature | 60-90 seconds at room temperature | 60-90 seconds at room temperature | 60-90 seconds at room temperature |

| Installed power | 5.95kw | 7.45kw | 8.55kw | 29.34kW |

| Total length of production line | 11 m | 13 m | 16 m | 28 m |