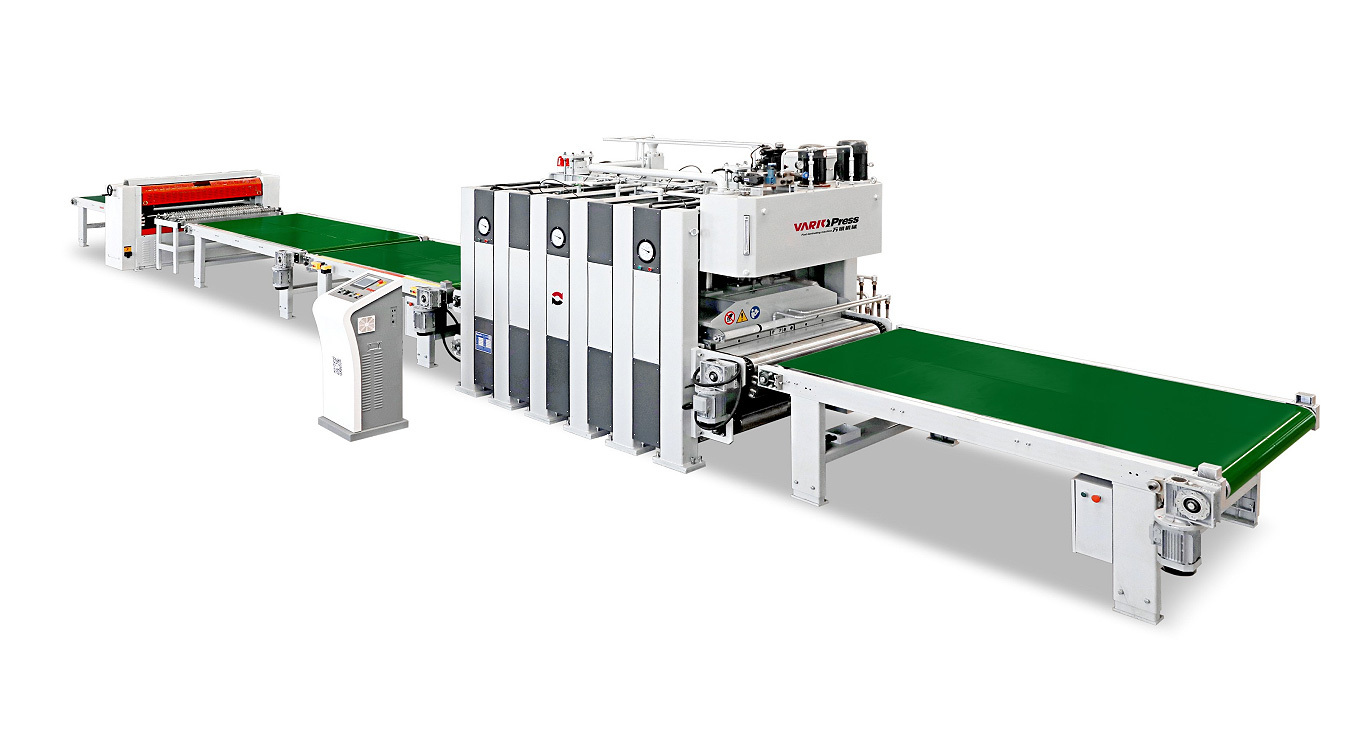

Laminating Production Line

Time: 2024-11-08

Fast cold pressing only takes 45-90s per door

Normal temperature rapid cold pressing average of each door pressing as long as 45-90s; thickness error in the range of ± 0.15mm.

Door frame double-sided coated with A glue, door plate single-sided coated with B glue, composite instantaneous drying water-based adhesive, can be formed in a short period of time a very strong initial bond; substrate, artificial blanking time, the ambient temperature of the different production beats are different.

Introducing our cutting-edge Laminating Production Line, a comprehensive solution designed to revolutionize the laminating process. Engineered for efficiency and precision, this advanced production line seamlessly integrates multiple stages of laminating, from material preparation to finishing, to deliver superior quality laminated products.

At the heart of our production line is state-of-the-art technology that ensures precise control over every aspect of the laminating process. From adhesive application to pressing, our automated systems guarantee uniformity and consistency, resulting in flawless laminated panels.

Versatility is a key feature of our laminating production line, allowing manufacturers to produce a wide range of laminated products to meet diverse customer demands. Whether it's decorative laminates for furniture or functional laminates for construction materials, our production line can accommodate various materials, sizes, and specifications.