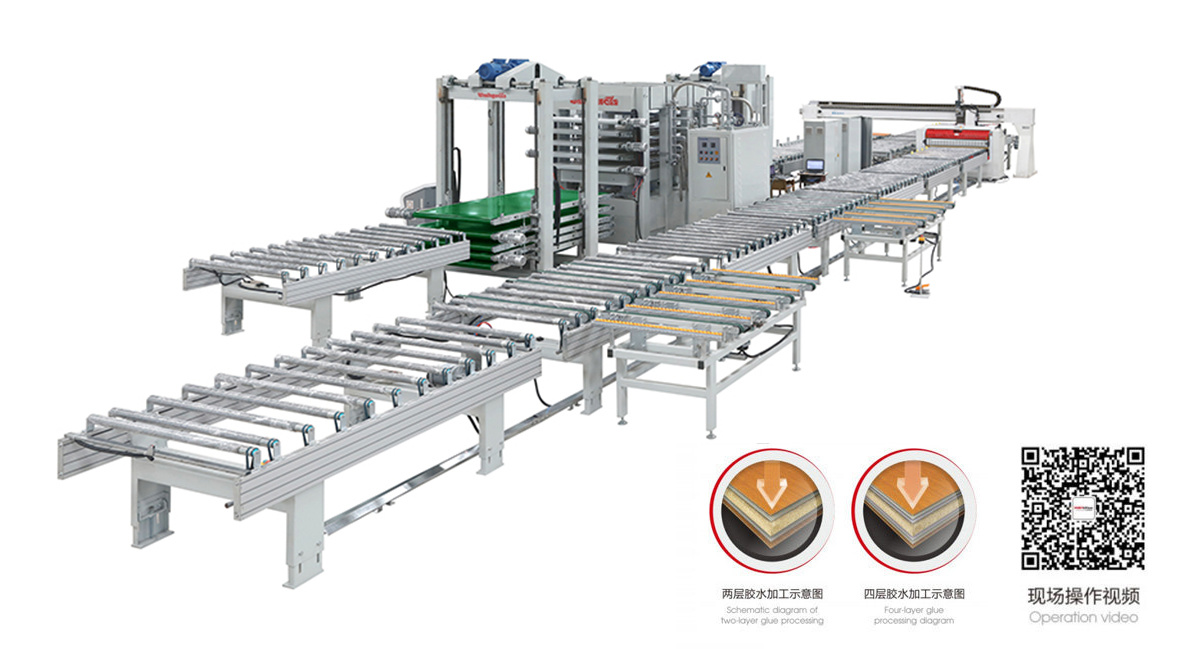

Laminated composite automatic production line

Time: 2024-11-08

The Five-layer Wooden Door Rapid Cold-pressing Laminating Production Line is a cutting-edge manufacturing solution tailored for the efficient production of high-quality wooden doors. The Laminated composite automatic production line is equipped with advanced machinery and technology that can seamlessly laminate five layers of wood together in a rapid and precise manner.

Starting from the preparation of raw materials to the final product finishing, this production line ensures consistent quality and uniform lamination of the wooden door panels. The rapid cold-pressing technology employed in this production line guarantees a fast turnaround time while maintaining the integrity of the wood.

The Five-layer Wooden Door Rapid Cold-pressing Laminating Production Line is designed to streamline the production process, reduce labor costs, and improve overall efficiency in wooden door manufacturing. Its automated features make it easy to operate, maintain, and customize according to specific production requirements.

In conclusion, the Five-layer Wooden Door Rapid Cold-pressing Laminating Production Line represents a significant advancement in the wooden door manufacturing industry, offering manufacturers a reliable and cost-effective solution for producing premium-quality wooden doors at scale.