Hot Press Machine for Plywood

Time: 2024-11-08

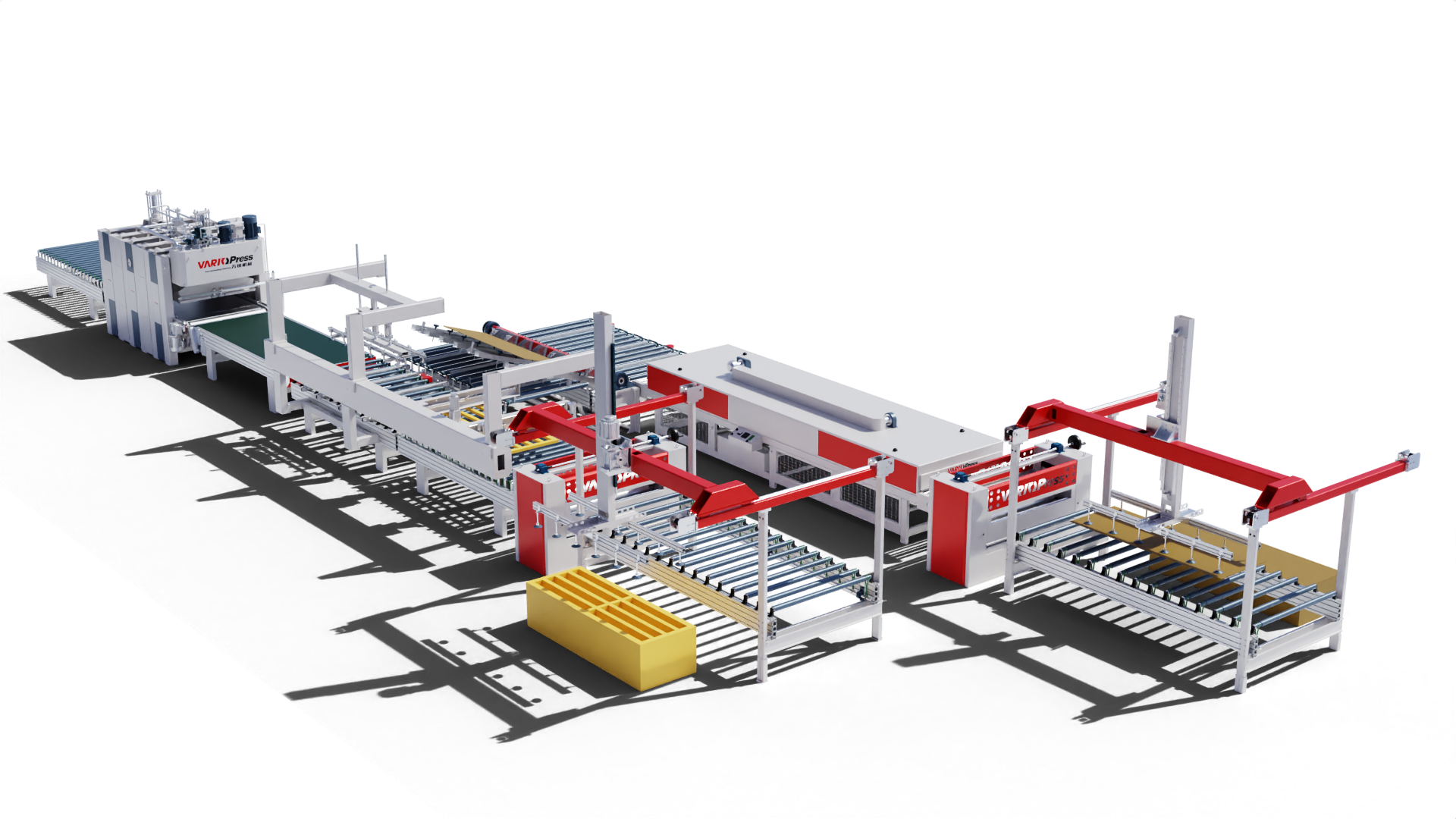

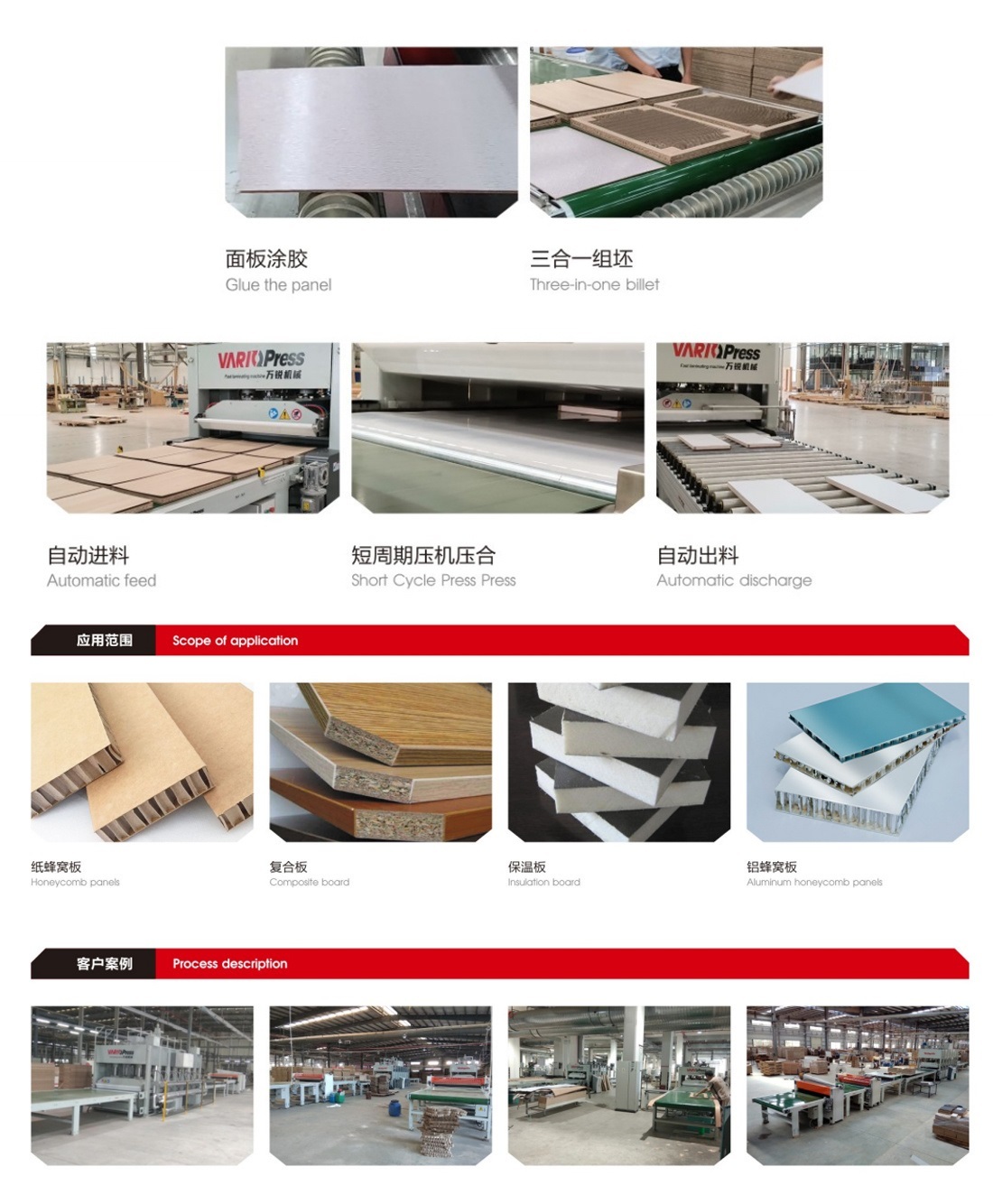

The Automatic Short Cycle Fast Composite Production Line is a cutting-edge manufacturing system designed to streamline the production of composite materials with short cycle times and high efficiency. This advanced production line leverages automation and innovative technologies to accelerate the manufacturing process, making it ideal for industries such as furniture production, interior design, automotive components, and construction materials.

Key Features of the Automatic Short Cycle Fast Composite Production Line include:

Rapid Cycle Times: The production line is optimized for fast cycle times, enabling quick turnaround of composite materials such as laminates, veneers, and decorative surfaces. This efficiency allows manufacturers to meet tight production schedules and increase productivity.

Automated Processes: Through automated material handling, pressing, heating, and cooling systems, the production line minimizes manual labor and human intervention, ensuring consistent quality and improving production reliability.

Versatile Applications: The production line is versatile and can be customized to produce a wide range of composite materials with different properties, finishes, and textures to meet specific industry requirements and design preferences.

Quality Assurance: Quality control measures are integrated into the production line to monitor and inspect the production process, ensuring the accuracy, integrity, and durability of the composite materials produced.

Energy Efficiency: The production line is designed to optimize energy consumption and minimize waste, making it a sustainable and cost-effective solution for composite material manufacturing.

The Automatic Short Cycle Fast Composite Production Line represents a significant advancement in composite material production, offering manufacturers a competitive edge in the fast-paced manufacturing environment. By combining speed, efficiency, quality, and versatility, this innovative production line is revolutionizing the production of composite materials across various industries.

Introducing our advanced Hot Press Machine for Plywood. Engineered for precision and efficiency, this machine ensures uniform heat distribution and optimal pressure for high-quality plywood production. With robust construction and automated controls, it streamlines operations, delivering consistent results and maximizing productivity. Elevate your woodworking capabilities with our Hot Press Machine for Plywood.

| Production line model | MT1-08 | MT1.1-01 | MT1.1-08 |

| Capacity output | 300 sets/8 hours | 500 sets/8 hours | 600 sets/8 hours |

| Staunching | 1 person | 2 people | 1 person |

| Glue process | Two-component cold-pressed quick-drying adhesive | Two-component cold-pressed quick-drying adhesive | Two-component cold-pressed quick-drying adhesive |

| Pressing time | 60-90 seconds at room temperature | 60-90 seconds at room temperature | 60-90 seconds at room temperature |

| Installed power | 29.34kW | 23.17kW | 35.62kW |

| Total length of production line | 28 m | 18.5 m | 27 m |