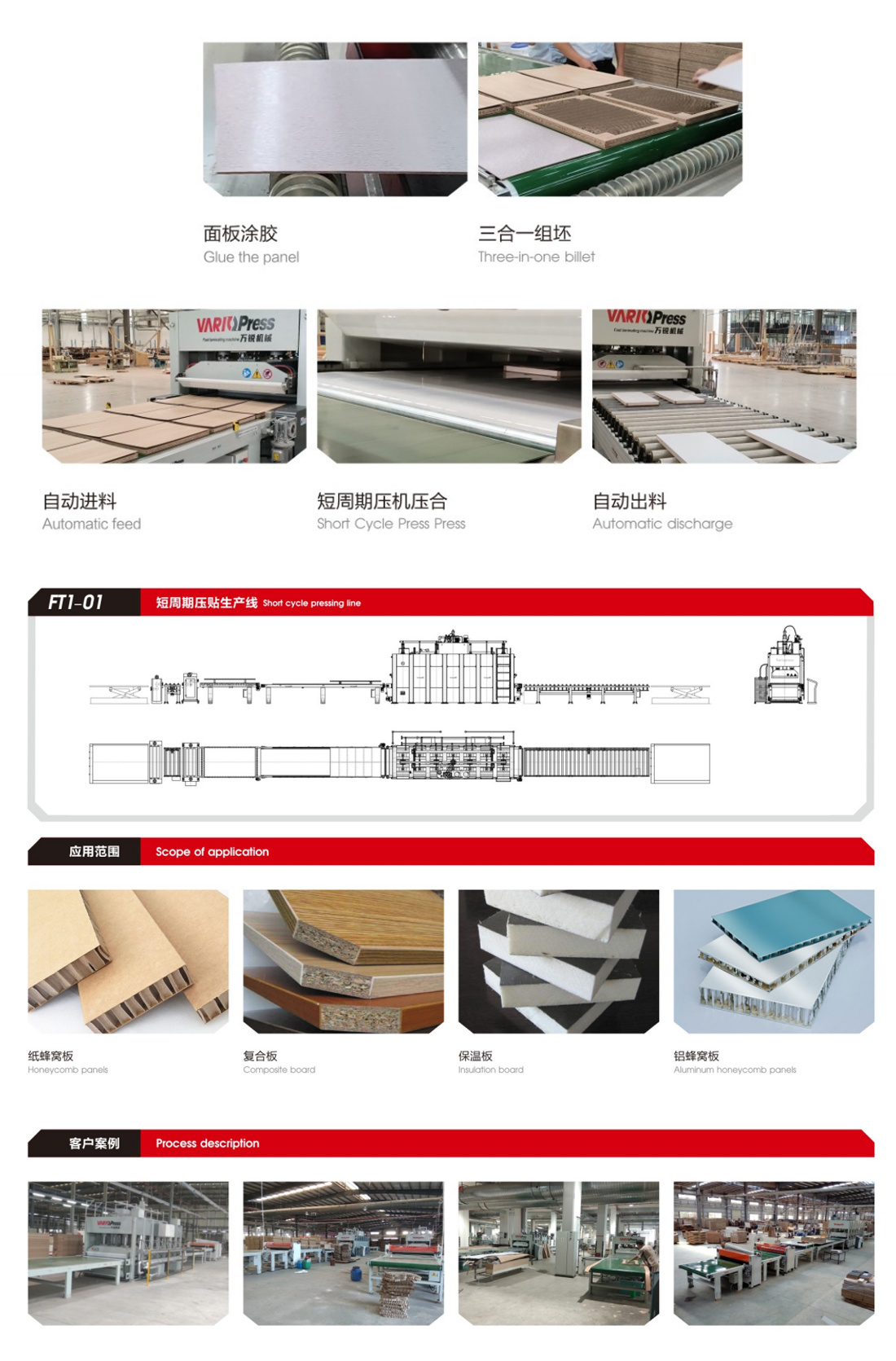

Honeycomb Automatic Composite Production Line

Time: 2024-11-08

The Honeycomb Automatic Composite Production Line is a state-of-the-art manufacturing system that enables the efficient production of honeycomb structures using composite materials, revolutionizing industries that rely on lightweight yet durable structural components. By automating key production processes, this advanced production line enhances the speed, precision, and quality of honeycomb panel manufacturing.

Benefits of the Honeycomb Automatic Composite Production Line include:

Increased Efficiency: Through automated material handling, bonding, and lamination processes, the production line significantly reduces production time and labor costs, allowing manufacturers to increase their output and meet the growing demand for honeycomb panels.

Enhanced Product Quality: The precise and consistent production processes of the production line ensure the uniformity and integrity of the honeycomb panels, resulting in high-quality products that meet stringent performance requirements.

Customization Options: The flexibility of the production line allows manufacturers to customize honeycomb panels based on specific design requirements, including variations in core materials, thicknesses, sizes, and surface finishes.

Sustainability: By optimizing material usage and minimizing waste through automated cutting and trimming processes, the production line promotes sustainable manufacturing practices in the production of honeycomb panels.

Overall, the Honeycomb Automatic Composite Production Line represents a significant advancement in composite manufacturing technology, offering manufacturers a competitive edge in producing lightweight, strong, and versatile honeycomb panels for diverse applications. With its focus on efficiency, quality, and customization, this innovative production line is shaping the future of honeycomb panel production in various industries.