Furniture Veneer Production Line

Time: 2024-11-08

The Furniture Veneer Production Line stands as a testament to the evolution of furniture manufacturing. This intricate system not only enhances the aesthetic appeal of furniture but also adds durability and longevity to the finished product.

At the core of this production line lies the meticulous process of veneer slicing. Logs of high-quality timber are carefully selected and then sliced into thin sheets of veneer. This precision slicing ensures that each sheet retains the natural grain and texture of the wood, making it an ideal material for furniture surfaces.

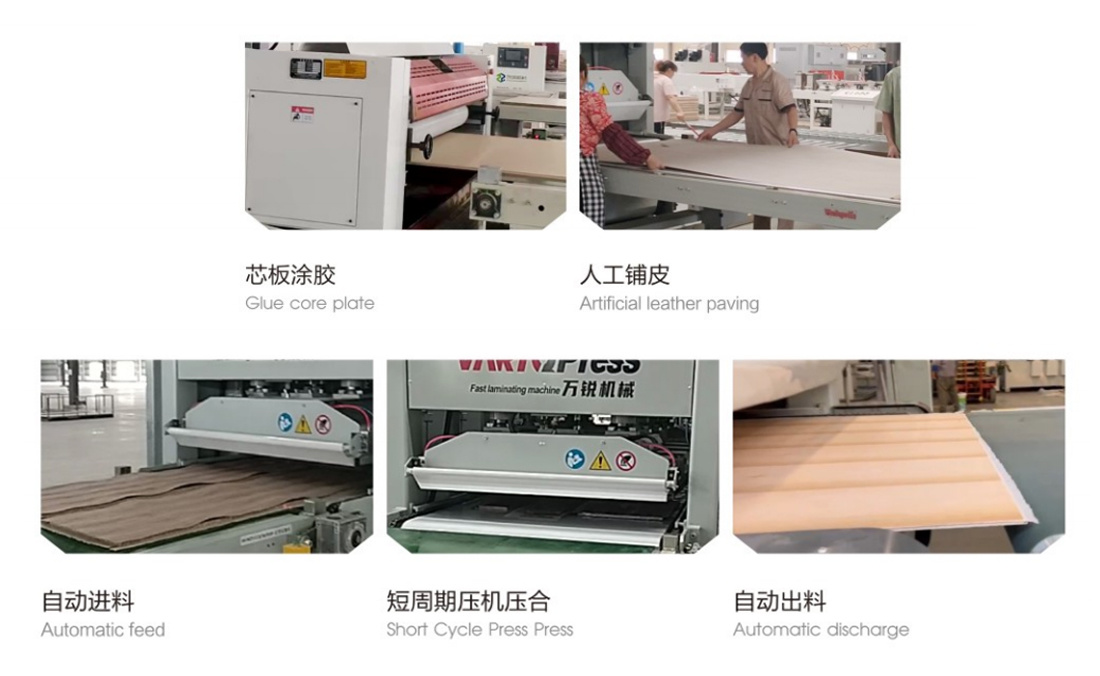

Once the veneer sheets are prepared, they are fed into the laminating machine. Here, multiple layers of veneer are bonded together under controlled conditions of temperature and pressure. The result is a strong and stable composite material that can be used to create a range of furniture designs.

The Furniture Veneer Production Line also incorporates advanced finishing techniques. This includes sanding and polishing the veneer surfaces to achieve a smooth and glossy finish. Additionally, the application of protective coatings adds durability and resistance to scratches and stains.

The efficiency of this production line is another noteworthy aspect. With automated feeding and control systems, the process is streamlined, reducing the need for manual labor and minimizing errors. This not only increases production speeds but also ensures consistent quality throughout the entire batch.

In conclusion, the Furniture Veneer Production Line represents the pinnacle of furniture manufacturing technology. It combines precision, durability, and efficiency to deliver high-quality veneer products that enhance the beauty and functionality of furniture.