MAIN APPLICATIONS

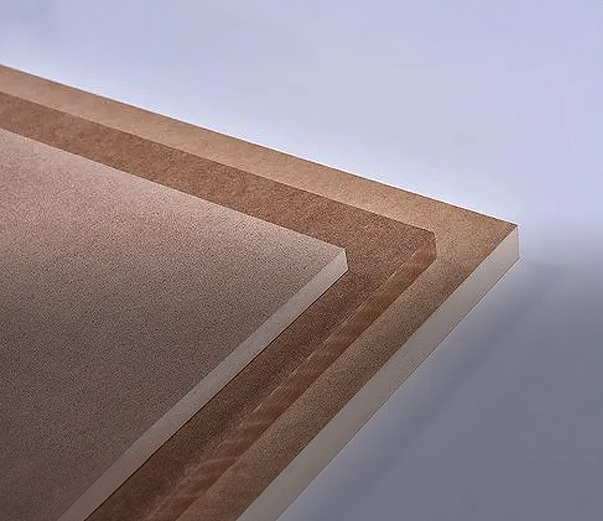

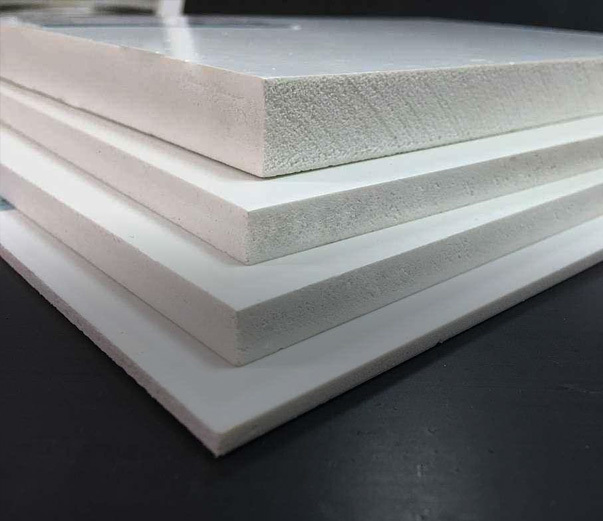

Complete set of equipment for pressing and laminating wood products

Learn More +Fiber Density Board, Plywood Density Board, Particle Density Board

Learn More +Synthetic and solid surfaces

Learn More +Automotive interior

Learn More +Expanded polystyrene (EPS)

Learn More +Special applications

Learn More +RECOMMENDED PRODUCTS

MT5-01

Five-layer Wooden Door Rapid Cold-pressing Laminating Production Line

Fast cold pressing only 60s a door

Learn moreABOUT VARIO

Foshan VARIO Machinery Co., Ltd.

Wanrui Machinery is a professional manufacturer integrating R&D, manufacturing, sales and service, and has been appraised as a science and technology-based small and medium-sized enterprise and a national high-tech enterprise. It is a member of China Forestry Machinery Association, China Furniture Association, Lunjiao Machinery Chamber of Commerce and Qingdao Machinery Association; it has been honored as "China's top ten wood processing machinery manufacturers in the wood machine industry, China's top ten door and window processing machinery manufacturers in the woodworking machinery industry". The company specializes in the production of wood processing hydraulic presses and intelligent pressure paste automated production line for wooden doors, customized home furnishing, building materials enterprises to provide pressure paste integrated application technology. With a unique understanding of the application of presses and twenty years of experience, the company focuses on the field of pressing and pasting, and develops a new generation of intelligent presses through the deep integration of process and software, control and machinery. Brand: Variopress.

CORE TECHNOLOGIES

Four core technologies

With the four core technologies of "stability, safety, cost reduction and energy saving", Wanrui Machinery has been satisfied and supported by many customers.These four core technologies of the product have been satisfied and supported by many customers, and so far it has served more than 4000+ customers.

Number of clients served

Stability overrides everything.

Years of experience, pressure paste technology is mature and stable, long-term stable processing is the guarantee of efficiency!

Security as always

Standardized production, continuous upgrading, stability and safety are our top priorities.

Costs are not as satisfactory as they could be.

Let the process automation, let the production of intelligent save time, save trouble, save wages, so that the profit maximization

Saving energy on a shoestring

Cold-pressure fast drying is more energy-saving, reaching the set pressure automatically locks, without additional power consumption.

VARIO NEWS

2025-03-24

Innovative Solutions for Industrial Challenges: Harnessing Intelligent Pressure Paste Technology to Revolutionize Manufacturing Processes

Innovative Solutions for Industrial Challenges: Intelligent Pressure Paste Technology Table of Contents 1. Introduction to Intelligent Pressure Paste Technology 2. What Is Pressure Paste Technology? 3. Benefits of Intelligent Pressure Paste Technology 4. Applications of Pressure Paste Technology in Industrial Manufacturing 5. How Intelligent Pressure Paste Technology Works

2025-03-21

Revolutionizing Manufacturing with Intelligent Pressure Paste Automated Production Lines

In the manufacturing industry, the integration of intelligent systems has led to significant advancements in production efficiency and quality. One such innovation is the intelligent pressure paste automated production line. This technology revolutionizes the way pressure paste is applied in various manufacturing processes, ensuring accurate and consistent application while minimizing waste. At th

2025-03-18

The Future of Woodworking: Hydraulic Presses as Game-Changers

The Future of Woodworking: Hydraulic Presses as Game-Changers Introduction to Hydraulic Presses in the Woodworking Industry The woodworking industry has long been associated with traditional craftsmanship, where skilled artisans shape wood into functional and decorative items. However, the integration of technology has introduced **hydraulic presses** as a game-changing tool that redefines the pos