Product show

Select by application scenario

Select by Mechanical Series

Product Showcase

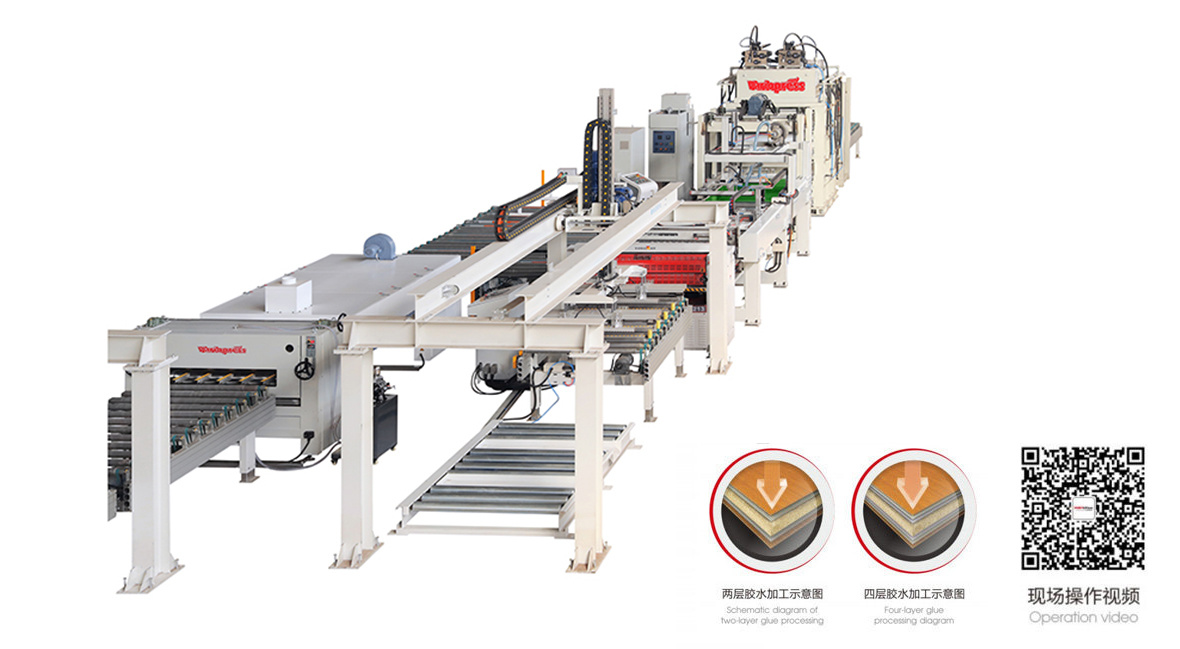

CT6-08

Paint-free door leaf cold-pressed composite production line

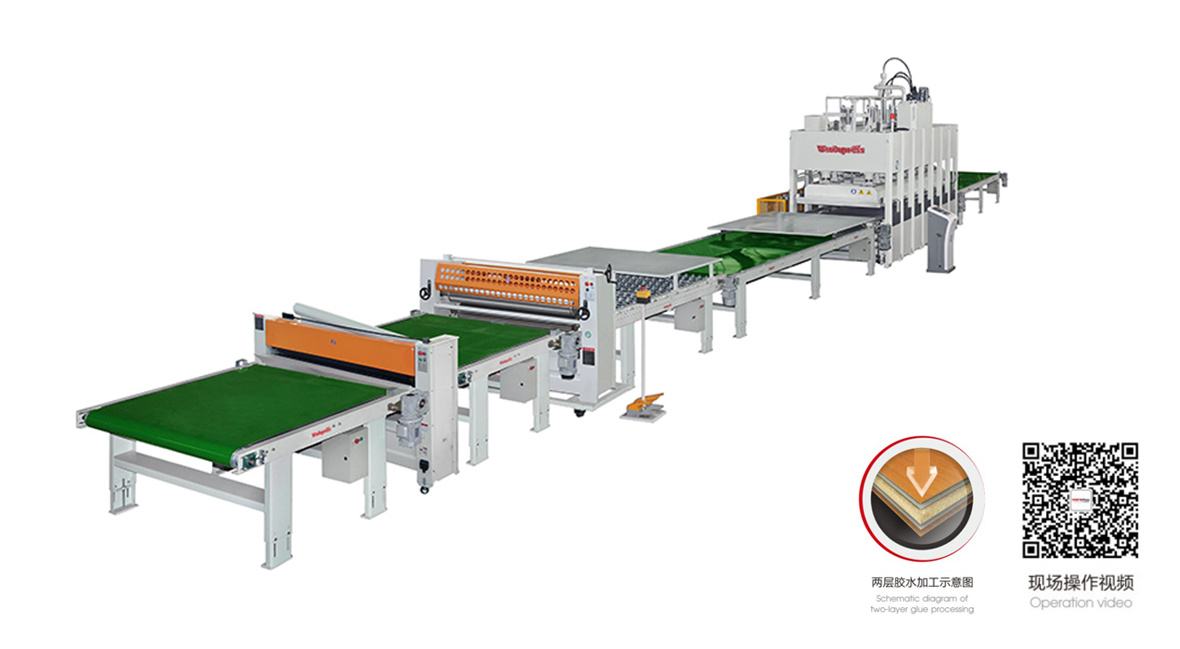

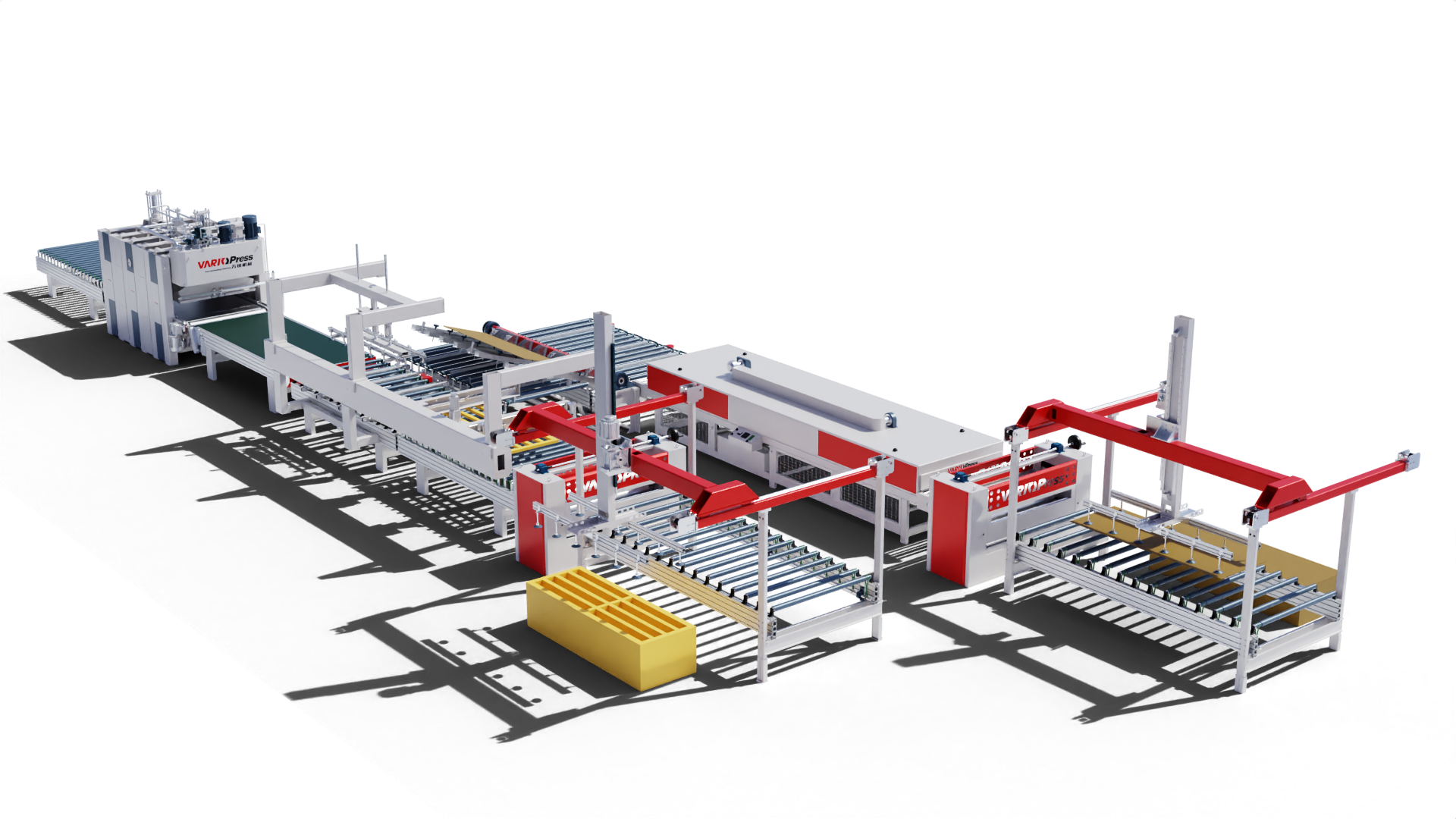

PT1-01

Automatic Flat Laminating Line

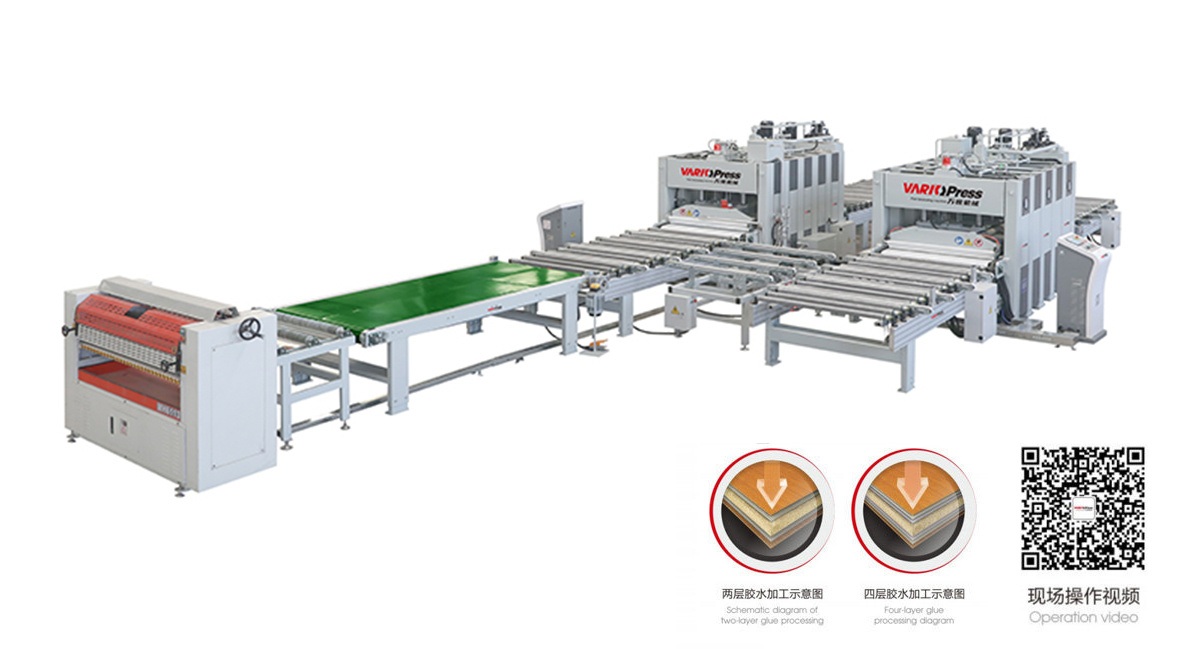

CT8-01

Paint-free door leaf cold-pressed composite production line

FT1-01

Honeycomb automatic composite production line

YT5-08

Five-layer furniture veneer production line

YT1-01

Furniture Veneer Production Line

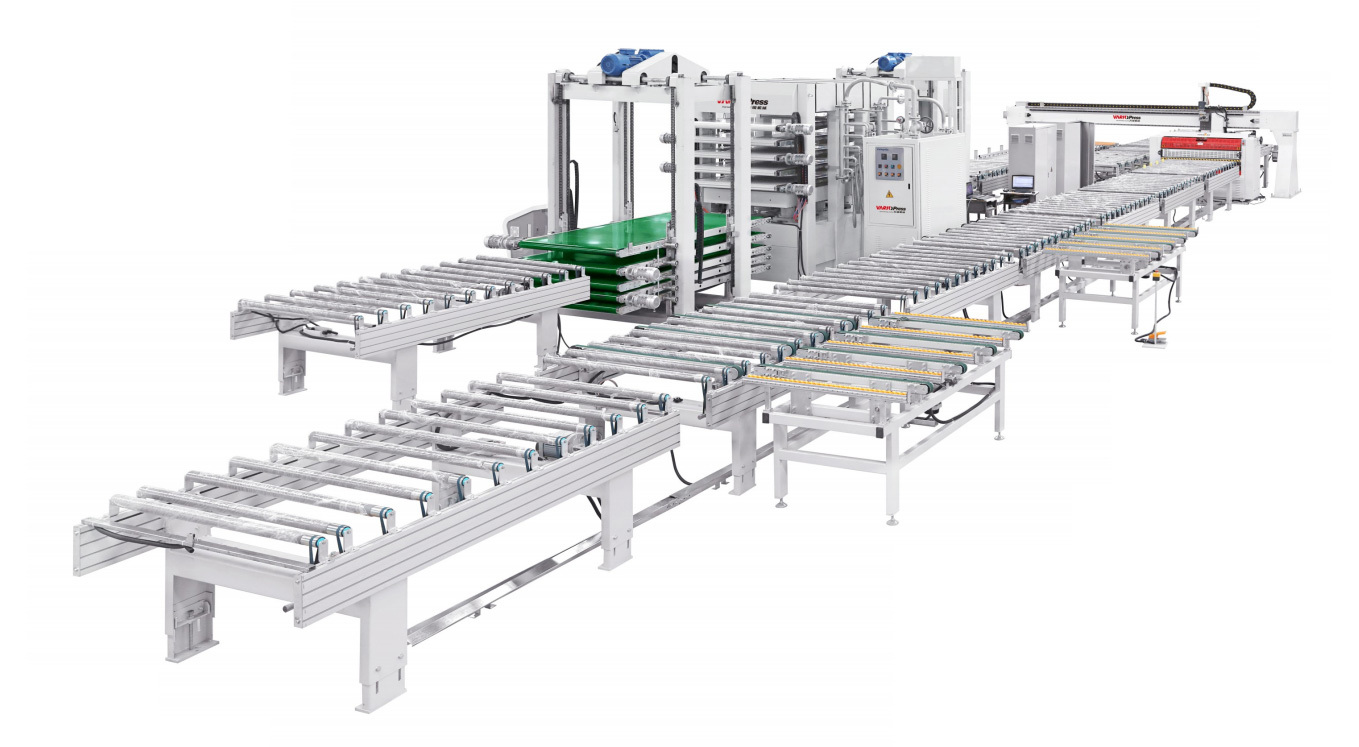

MT5-08

Five-layer wooden door rapid cold pressing composite production line

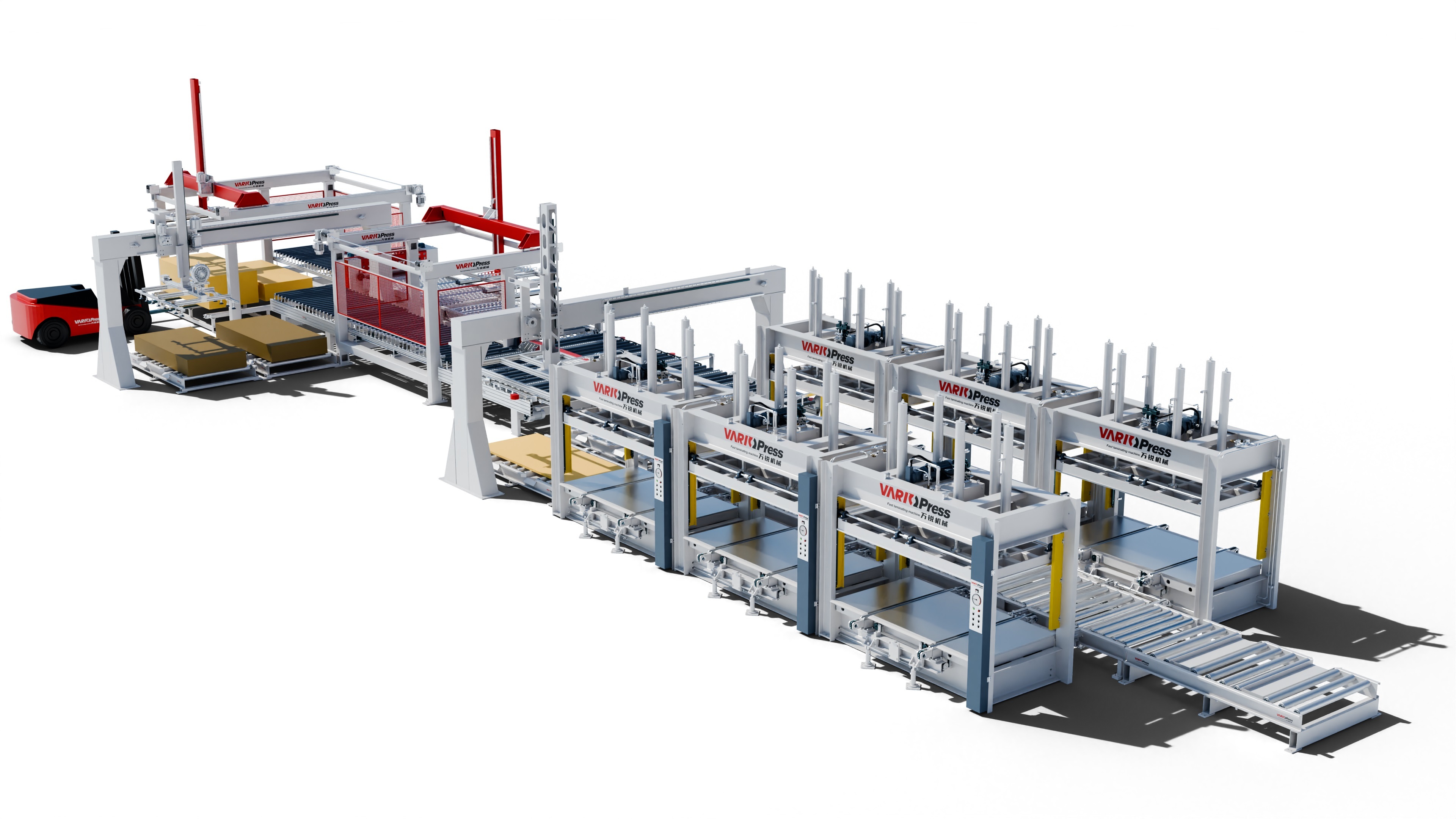

MT2-08

Stacked two-layer type door cold pressing composite automatic production line

MT1-08

MT wooden door composite series-MT1-08 automatic short cycle fast composite production line

MT1.1-01

MT Wooden Door Composite Series-MT1.1-01 Wooden Door Short Cycle Fast Composite Production Line

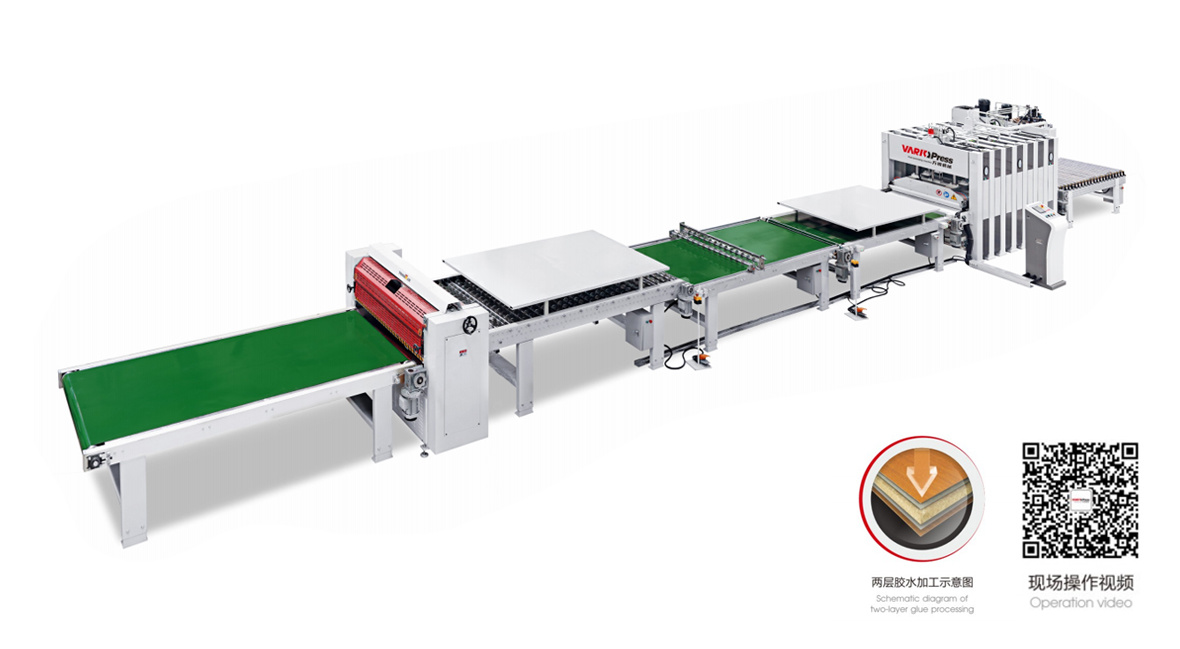

MT1-010

Wooden door short cycle fast laminating production line

MT5-01

Five-layer Wooden Door Rapid Cold-pressing Laminating Production Line

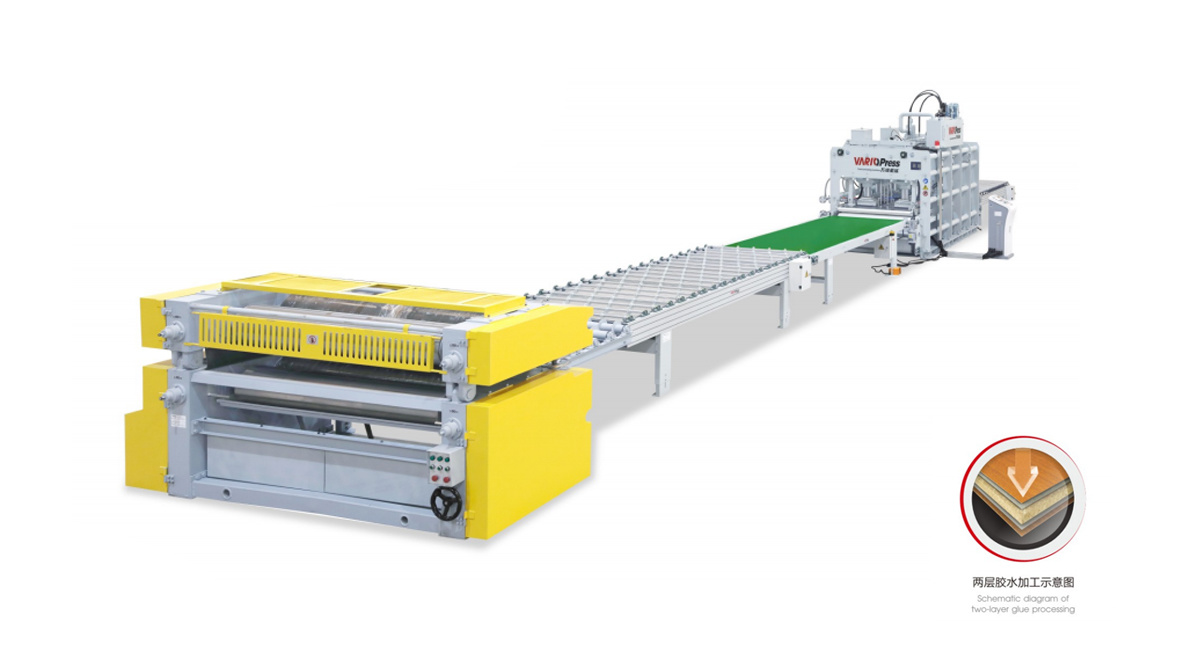

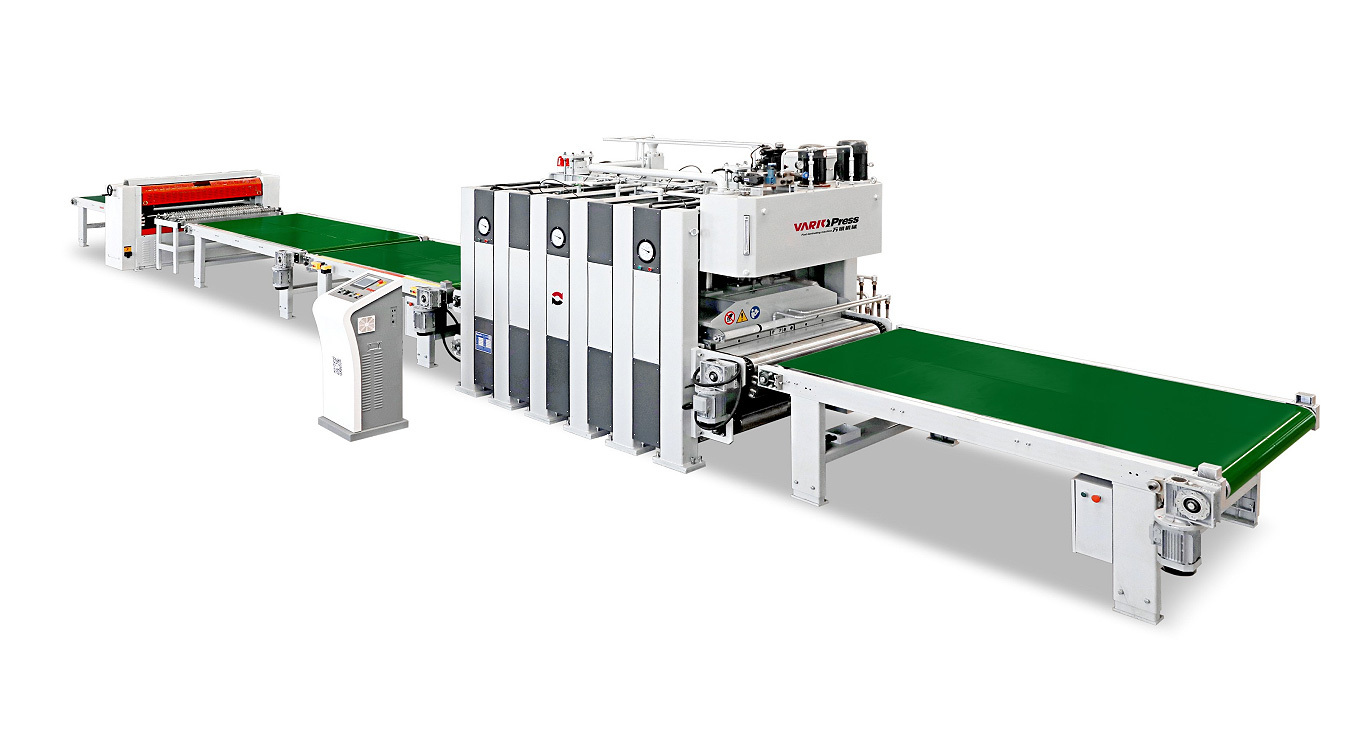

100 Ton Hot Press Series - 100 Ton Hot Press